FEATURES:

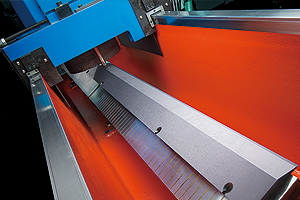

High Precision Slideways

- The longitudinal feed slideways employ Germany-imported guideways featuring and maximum wear- resistance.

- The slideways are pretensioned for minimum deformation.

Manual Pulse Generator (MPG)

MPG allows for job control of vertical and longitudinal movement and added convenience of setup.

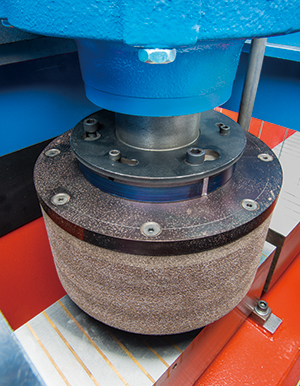

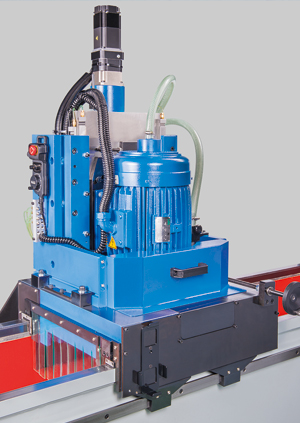

Stable Grinding Head

- The grinding head is driven by a 15HP motor.

- High precision wheel spindle is dynamically balanced for smooth running.

Downfeed Control of Grinding Head

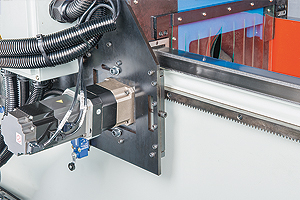

The grinding head downfeed is driven by a servomotor which is directly coupled to a ball screw, providing high positioning accuracy and low backlash.

Rigid Grinding Head Carriage- The grinding head carriage moves on bearings for smooth movement.

- The extra wide carriage construction in combination with great span between bearings ensures extremely uniform load distribution and increased rigidity and stability.

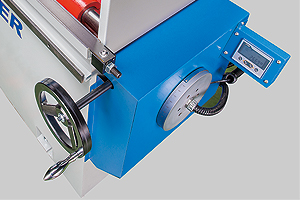

Magnetic Table

- This machine is equipped with a magnetic table for fast knife clamping and unclamping.

- Each magnetic table measures 150 mm wide.

- Magnetic table can be tilted and tilting degree is displayed on a digital readout.

Coolant System

- The coolant is pumped by a coolant pump that discharges coolant to the point of contact between the grinding wheel and the knife. This permits a heavier cut for the grinding wheel without injurious overheat of the cutting edge of the knife and thereby shortens the time required to grind.

- The coolant tank is equipped with filter for reclamation of the used coolant.

Longitudinal Feed of Head Carriage

- Longitudinal feed of head carriage is driven by a servomotor and transmitted through a rack/pinion mechanism for extremely smooth movement.

- Grinding length can be varied by adjusting the position of length stops.