| STANDARD EQUIPMENT: |

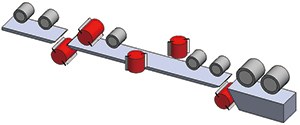

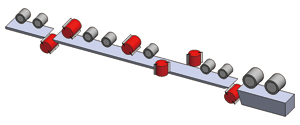

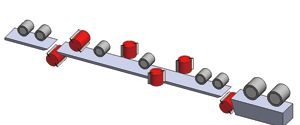

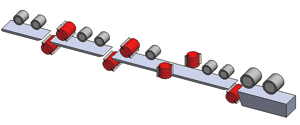

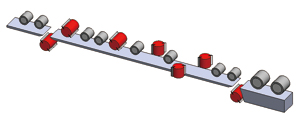

LMC-223SP to LMC1123SP |

Available Options |

| Number of Heads / Spindles, min-max |

2 to 11 |

Any Head Configuration - available |

| Working Width (with a tool cutting circle of 163mm) |

20-230mm (0.78"-9") |

to 310mm (12.2"), 330mm (13") |

| Working Thickness (with a tool cutting circle of 163mm) |

10-150mm (0.39"-6") |

to 6mm (.25") to 200 (8") |

| Basic Spindle Motor capacity - Wye-Delta (Soft Starts) on all motors |

11/12KW (15HP) |

to 37.5KW / 50HP

|

| Spindle Diameter |

50mm |

1 13/16" / 2 1/8" |

| Spindle Speed |

6000 RPM |

7200 / 8000 RPM |

| Tool cutting circle, First Bottom Spindle, min-max |

125-200mm (5"-7.8") |

|

| Tool cutting circle, Vertical Spindles, min-max |

140-250mm (5.5"-9.8") |

|

| Tool cutting circle, Horizontal Spindles, min-max |

140--250mm (5.5"-9.8") |

|

| Feed Motor |

11KW / 15HP / INVERTER |

15 / 18.5KW (20 / 25HP / INVERTER)

|

| Feed speed, infinitely variable by frequency (VFD) driven |

6-60 m/min (20 / 200fpm) |

9-90m/min (30-300fpm) |

| Top Infeed Rolls - Diameter |

205.36mm (8") |

|

| other Top Feed Rolls - Diameter |

140mm (5.5") |

|

| Top Feed Roll Width - Multiple Rolls Stacked on each Top Roll Shaft |

50mm (2") / Roll |

|

| Bottom Feed Roll Width |

Full Width |

|

| Pneumatic pressure for feed rollers, max |

6 bar (85psi) |

|

| Adjustment range for Infeed Table (Btm Head Cut) and Edge Jointing Fence |

10mm (.4") |

|

| Adjustment range of vertical spindles (axial) |

80mm (3.2") |

|

| Adjustment range of horizontal spindles (axial) |

40mm (1.6") |

|

| Length of the Infeed / Straightening table |

0.8M (32") |

1.4 / 2 / 2.5 / 3M (55" / 78" / 98" / 120") |

| Diameter of Dust Hoods for Vertical & Horizontal Spindles |

Ø175mm (6.9") |

|

| Digital Readouts on All Axis of all Heads |

Std. |

|

| Digital Readouts for the Chip Breaker Shoes & Pressure Shoes |

Std. |

|

| Full Sound and Safety Enclosure w/ Strobe Free Lighting |

Std. |

|

| Motorized vertical adjustment of Feed Beam |

Std. |

|

| Multiple Lateral Pneumatic Pressure Roller opposite first right spindle |

Std. |

|

Chainless Extra HD Cardan Shaft Feed System

|

Std. |

|

| REC Setworks on Near Side Head (s) & Top (s) - Radial |

Std. |

|

● All specifications, dimensions and design characteristics are subject to change without notice.

| OPTIONAL EQUIPMENT : |

| Straight &/or Profile Jointers any heads |

Grooved Bed for running very short material |

| Electronic Rotary Encoder Digital Readouts in lieu of mechancial counters |

Split Pressure Shoes |

| Extra HD Feedworks; Bottom top Head Configuration for rough materail feeding |

Opposed Side Heads |

| Tilting Side Heads |

Universal Spindle, tool cutting circle min 125mm, max 200mm |

Tilting Top Beam, Tilting Feed, Tilting Feedworks, Tilting top Head Chipbreaker Ass'y,

Tilting Pressure Plate(s) |

Rip Saw Section with up to 56kw(75HP)

Left(Opposite) Hand Feed

Inverter Motor Cutterhead Brakes |