| STANDARD EQUIPMENT / Planermc - LMC 245PL to LMC11106PL |

Standard Base Equipment |

Available Options |

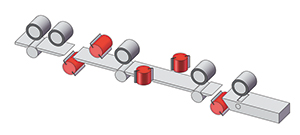

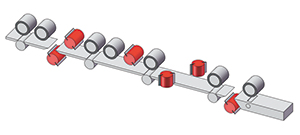

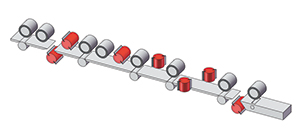

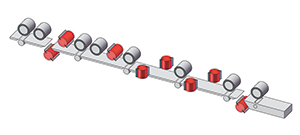

| Number of Spindles, min-max |

2 to 11 |

Special Machine Configurations on request |

| Working Width (at a tool cutting circle of 125mm-200mm) |

15~450mm (0.59"~17.7") |

500mm (20") ; 600mm (24") ; 700mm (27.5") ; 1300mm (51.1") |

| Working Thickness (at a tool cutting circle of 125mm-200mm) |

10~200mm (0.39"~7.1") |

to 200mm (8") ; to 250mm (10") ; to 300mm (12") ;or to 350mm (14") |

| Basic Spindle Motor capacity (Wye Delta Soft Starts on All Motors) |

11 KW / 15HP |

to 75KW (100HP) |

| Spindle Speed |

5500 RPM |

6000 RPM or 7200 RPM |

| Spindle Diameter |

50mm (2") |

1 13/16" or 2 1/8" |

| Tool Cutting Circle,1st Bottom Spindle, min-max |

125~180mm (5"~7.1") |

|

| Tool Cutting Circle, Vertical Spindles, Left, min-max |

125~200mm (5"~8") |

to 250mm (10") |

| Tool Cutting Circle, Vertical Spindles, Right, min-max |

125~200mm (5"~8") |

to 250mm (10") |

| Tool Cutting Circle, Horizontal Spindles, Top, min-max |

125~200mm (5"~8") |

to 250mm (10") |

| Tool cutting circle, Horizontal Spindles, Bottom, min-max |

125~200mm (5"~8") |

to 250mm (10") |

| Feed Motor |

3.7 KW / 5HP / INVERTER |

to 15kw (25 HP) |

| Feed Speed, infinitely variable by VFD Inverter duty Motor |

6~24 m/min (20~80FPM) |

to 36mpm (120fpm) ; 48mpm (160fpm) ; 60mpm (200fpm) or 90mpm (300fpm) |

| Top Feed Roller Diameter |

200mm (8") |

|

| Top Feed Roller Width |

4 x 50mm (2") |

|

| Pneumatic Pressure for feed rollers, max |

6 bar (85psi) |

|

| Adjustment range for infeed table and edge-jointing fence |

10mm (0.4") |

|

| Adjustment range for vertical spindle (axial) |

40mm (1.57") |

|

| Adjustment range for horizontal spindle (axial) |

20mm (0.78") |

|

| Length of the Infeed Straightening Table |

1.4M (55") |

1M (39") ; 2M (78") ; 2.5M (98") or 3M (120") |

| Mechanical digital readouts for the pressure shoes & hold-down unit |

Included |

|

| Full Sound and Safety Enclosure w/ Strobe-free Lighting |

Included |

Extra Insulation with Steel Punched Sheet Steel Ineterior |

| Motorized vertical adjustment of Feed Beam |

Included |

|

| Pneumatic Lateral Pressure Roller System opposite first right spindle |

Included |

|

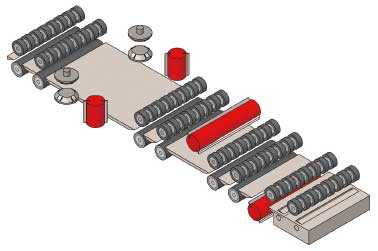

| Extra HD Chainless Cardan Shaft Feed System w/ExHD Gearboxes |

Included |

|

| Quick Set Setworks on Near Side Head (s) & Top Heads (Radial Set) |

Included |

optional on all Axis and SmartSet Controls as noted Below optional |

● All specifications, dimensions and design characteristics are subject to change without notice.

| OPTIONAL EQUIPMENT : |

| To CE Standards |

Setting and Measuring Devices for the grinding room |

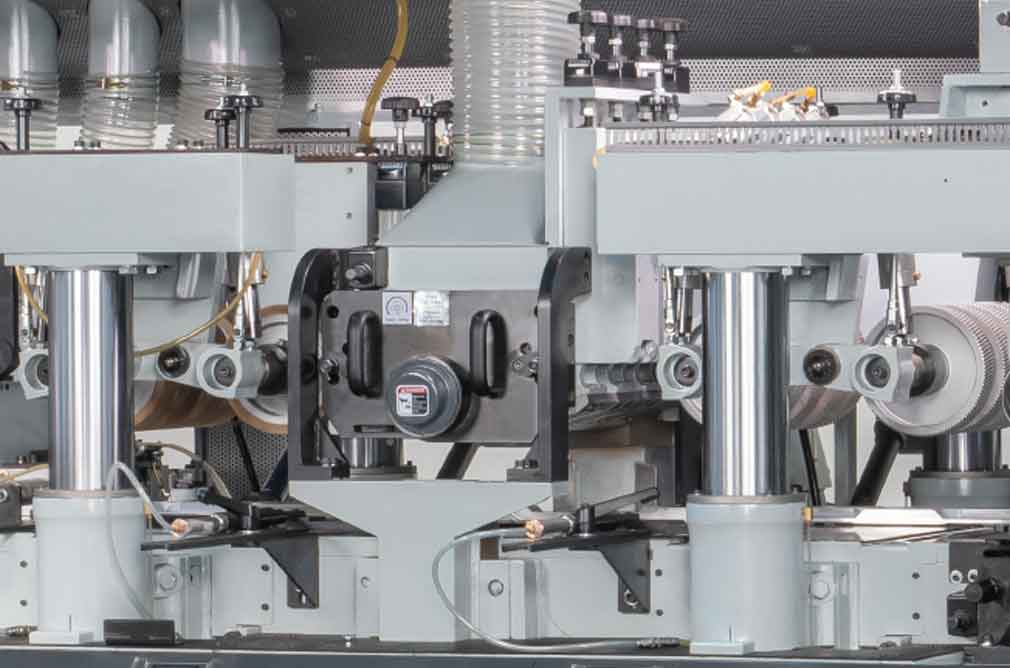

| Chanfering Heads for Material Corners |

SINGLE Digital Readout and Quick Set to Main guide & Infeed Rolls-table |

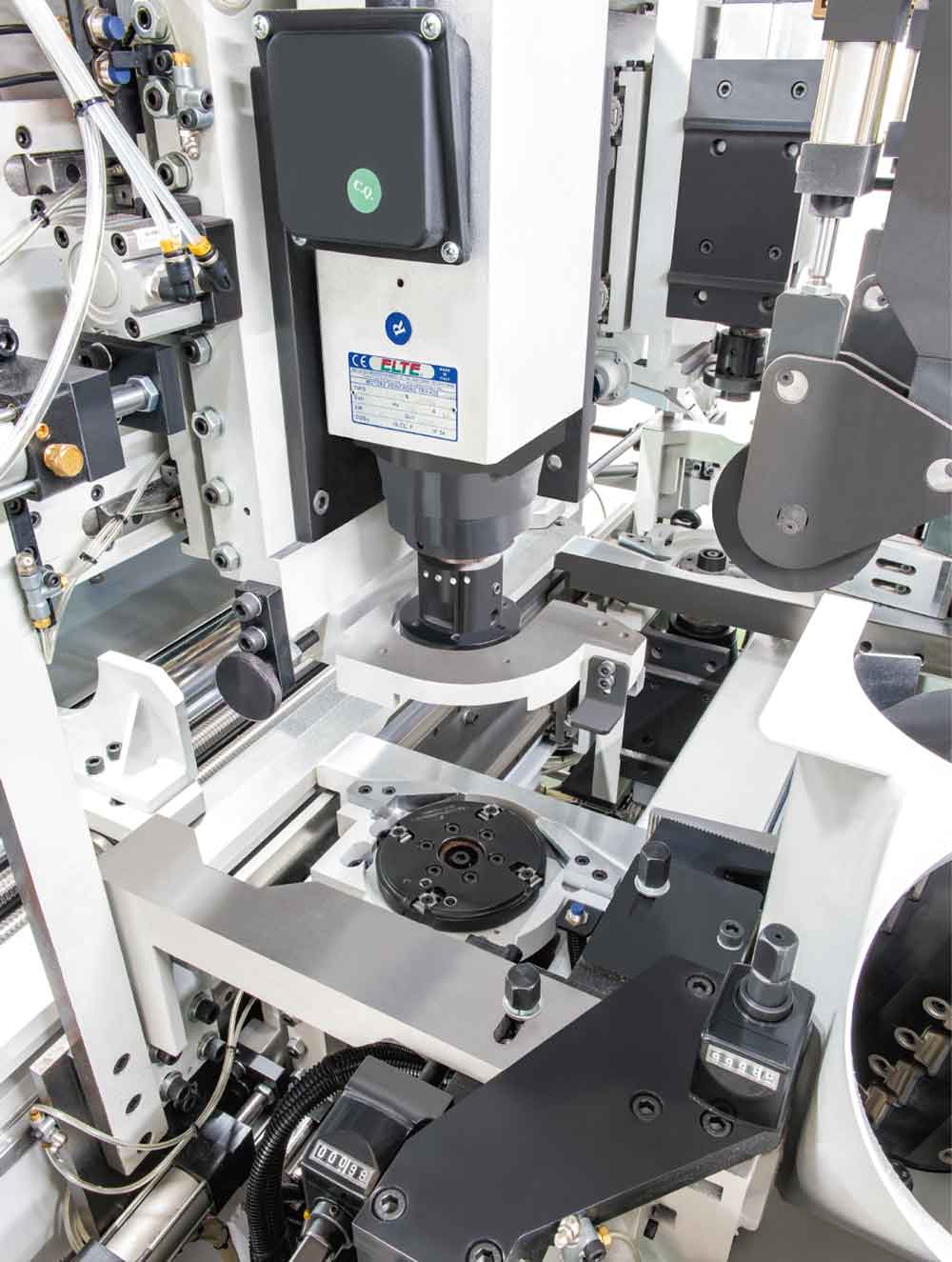

| Straight &/or Profile Jointers any heads |

(1, 1.4 & 2M Table) |

| Tilting Side Heads |

Additional Quick Set Setworks on any desired Cutterhead Axis |

| Split Pressure Shoes |

Outboard Top Feed roll Bearing Supports (optional on 450mm machine - Std. on all other |

| Directly Opposed Side Heads |

machines |

| Rip Saw Section with up to 75kw (100HP) |

Electronic Rotary Encoder Digital Readouts in lieu of mechancial counters - not required |

| Left (Opposite) Hand Feed |

with SmartSet Controls as included |

| Inverter Motor Cutterhead Brakes |

Hydro-Loc Outboards for Side Head Shafts that are 300mm(12") or 350mm(14") long |

| Cutterhead Lift Off Crane |

|