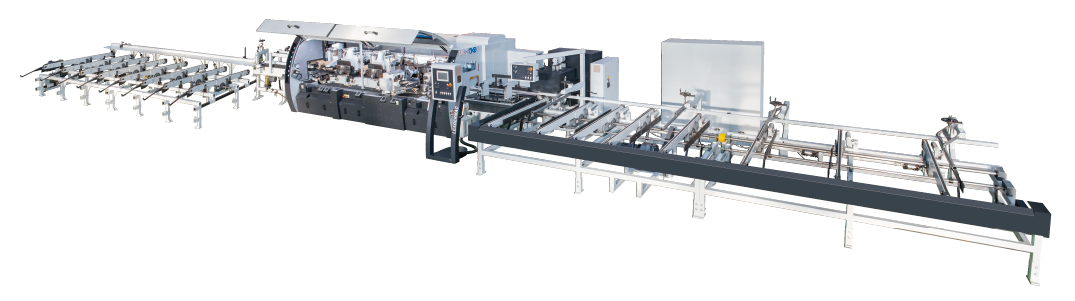

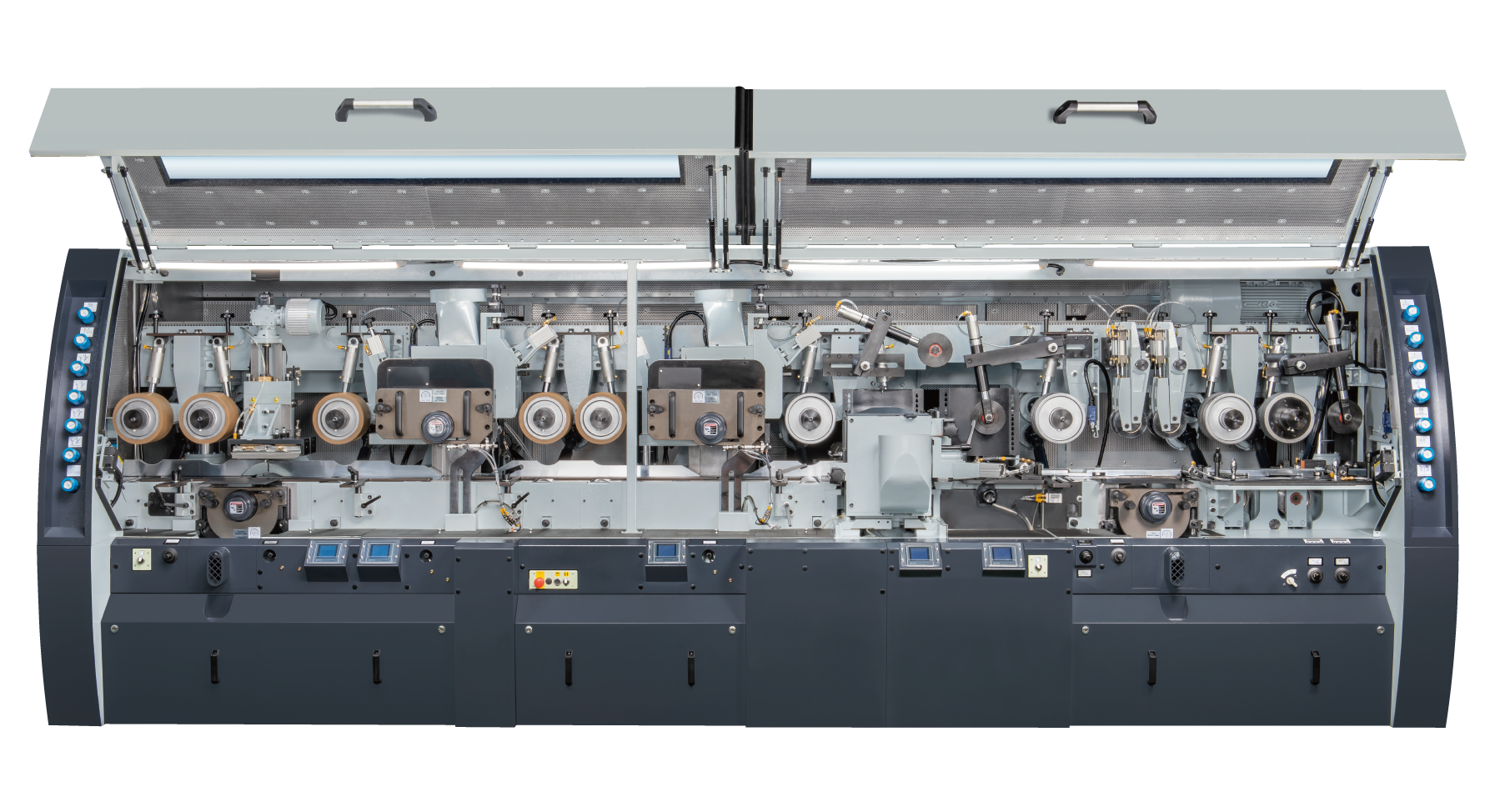

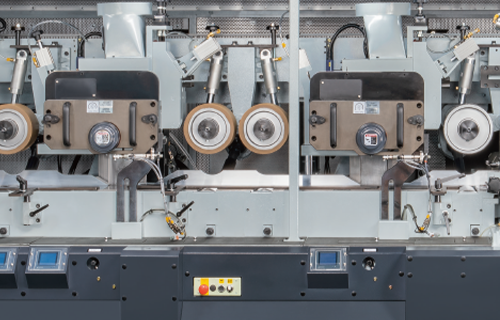

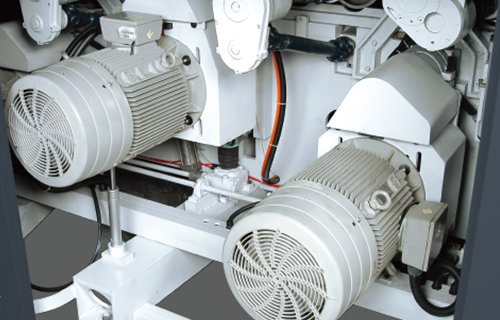

The Leadermac Thundermac Series 4-side Planer/Moulder was developed with the aim of improving productivity and surface finish. The Thundermac Series features high feed speed of up to 80 M/min (265 FPM) as standard and optional extra high feed speed of up to 200 M/min (656 FPM). is available. Each spindle is driven by an individual 15 & 22 KW / 20 & 30 HP Motor and optional to 45 KW (60 HP), allowing for heavy cutting. A wide range of spindle configurations from 2 to 10 Spindles provide flexible choice to meet specific moulding requirement. Maximum stability during high speed is attainable thanks to the rugged construction throughout.

Equipped with a user-friendly Programmable Controller, the desired values for width and thickness can be conveniently pre-set and are displayed on the LED readout. (Optional)

FULLY AUTOMATIC FEEDING SYSTEM (Optional)

When the system detects the workpiece on the infeed chains, the hydraulic feed system will pneumatically lower and activate the top roller to feed the workpiece into the machine. This provides constant and stable feed, reducing labor requirements and decreasing cycle time.

(Other configurations available on request)

Built for super-high production requirements, the Thundermac Series of 4-Sided Planer/Moulders can bring your production speed to a new level.

The Thundermac Series is designed for high-capacity, highly quality operations for large and small batch production runs. The heavy-duty spindles are dynamically balanced and run in premium housing bearings, for superior workpiece finish quality.

The Thundermac provides perfect surface quality, eliminating the need for sanding on planed and profiled surfaces.

4 Good Reasons To Buy Leadermac Moulders

Every 4-side moulder from Leadermac is built with Leadermac's traditional Quality Excellence, maximum dependability of performance year after year combined with comprehensive technological service.

230mm (9”) LMC-223T (2-spindle) to LMC-1023T (10-spindle) or 305mm (12”) LMC-230T (2-spindle) to LMC-1030T (10-spindle)

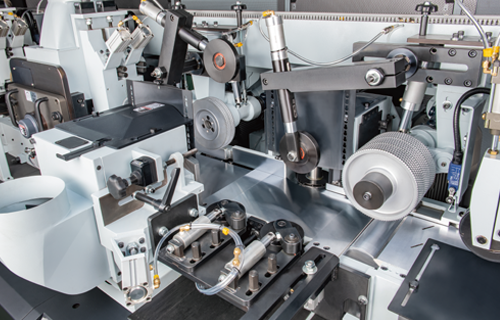

The infeed rolls work in conjunction with a limit switch (anti double-up gate) to stop the machine feed if the workpiece is too thick or there is double up.

The machine comes equipped with an automatic lubricator, which automatically delivers lubrication oil to the feed table, ensuring smooth feed at all times.

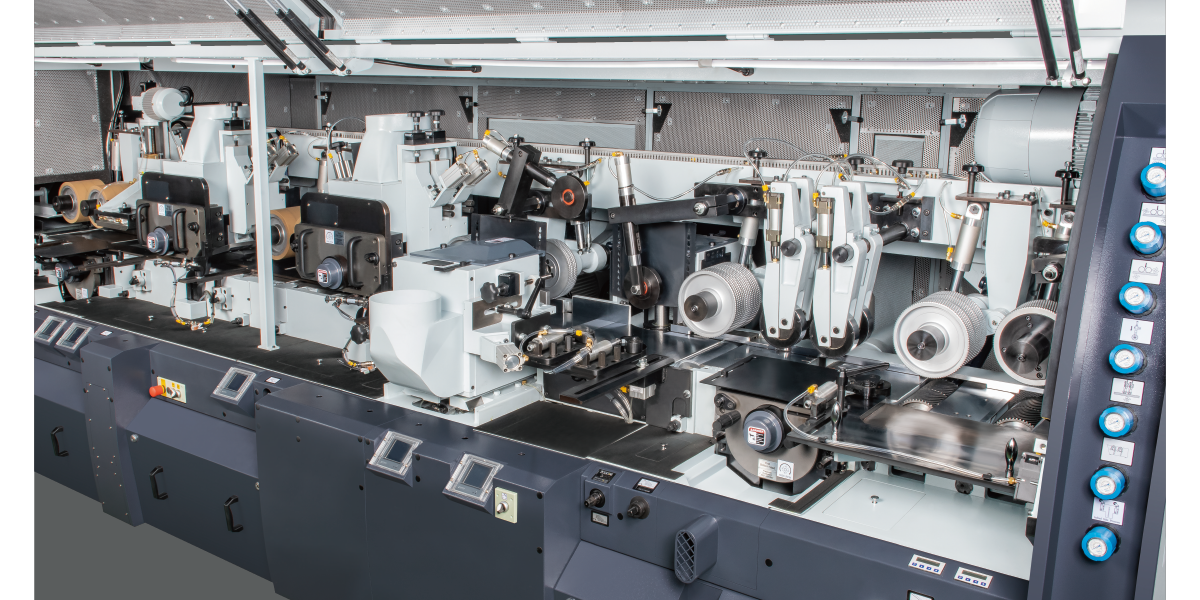

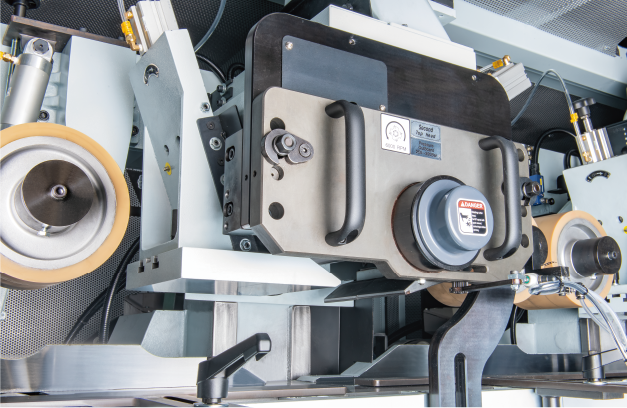

The lock device is designed with two air cylinders to tighten the hydro-bearing housing to achieve dependable locking function. The top air cylinder actuates to tighten the hydro-bearing housing in Axial direction, while the bottom air cylinder is used for tightening in Radial direction.

Powerful, heavy-duty pneumatic side and pressure shoes for the left spindle provide extremely stable pressure for high-speed operations. A pneumatic Top Pressure Roller System in front of the right vertical spindle ensures constant stock feed.

POWERED INFEED ROLLERThe smooth initial feeding of the stock is achieved by means of the independently powered Top & Bottom Infeed Rolls.

Adjustment of all spindles is easily done from the front. The adjustment points are all at the same height, for more convenient and faster adjustment.

The feed rollers are driven through a combination of universal shafts and gearboxes, ensuring no loss of power transmission. A smooth feeding effect is assured. Heavy duty gearboxes have no backlash and provides powerful and accurate feeding performance.

The Thundermac Series will show you how to boost your Planer / Moulding Productivity

Utilizing housing bearings, the reliable hydro-clamping system ensures consistent quality across the entire workpiece. The unit performs admirably even during high-speed continuous operation. The spindles can be adjusted axially even if the housing bearings are locked.

The speed is VFD Inverter controlled, and all electrical components meet CE, UL & CSA standards.

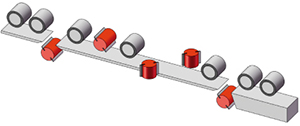

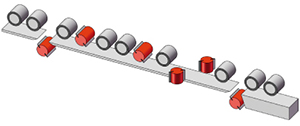

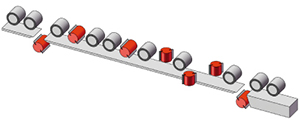

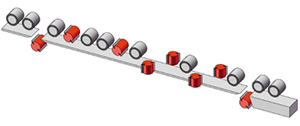

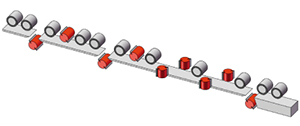

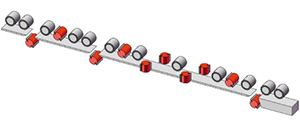

A Wide Range of Spindle Configurations (other configurations available on request)

LMC-523 5-SPINDLE

LMC-623 6-SPINDLE

LMC-723 7-SPINDLE

LMC-823 8-SPINDLE

LMC-1023 10-SPINDLE

| STANDARD EQUIPMENT LMC 223T to LMC 1023T or LMC 230T to LMC 1030T : | Available Options | |

| Number of Spindles (Min - Max) | 2 to 10 | |

| Working width (with a head cutting circle of 163mm) | 20~230mm (0.78"~9.1") | 300mm (12") |

| Working Thickness (with a head cutting circle of 163mm) | 10~150mm (0.39"~6") | to 200mm (8") |

| Basic Spindle Motor capacity (Wye Delta Soft Starts on All Motors) | 15 & 22 KW / 20 & 30HP | to 45KW (60HP) |

| Spindle Speed | 6000 RPM | 7200 RPM or 8000 RPM |

| Spindle Diameter | 50mm or 1 13/16" or 2 1/8" | |

| Tool Cutting Circle,1st Bottom Spindle, min-max | 160~260mm (6.3"~10.25") | |

| Tool Cutting Circle, Vertical Spindles,min-max | 160~260mm (6.3"~10.25") | |

| Tool Cutting Circle, Horizontal Spindles, Top, min-max | 160~260mm (6.3"~10.25") | |

| Tool cutting circle, Horizontal Spindles, Bottom, min-max | 160~260mm (6.3"~10.25") | |

| Feed Motor - Standard | 15 KW / 20HP | to 30kw (40 HP) |

| Feed Speed, infinitely variable by VFD Inverter duty Motor | 8-80 m/min (25~265FPM) | 120m/min(400FPM), 160m/min(533FPM), 200m/min(656FPM) |

| Top Feed Roller Diameter | 205.36mm (8") | |

| Top Feed Roller Width | 3 x 50mm (2") | |

| Pneumatic Pressure for feed rollers, max | 6 bar (85psi) | |

| Adjustment range for Infeed Table and edge-jointing Fence | 10mm (0.4") | |

| Adjustment range for Vertical Spindles (axial) | 80mm (3.2") | |

| Adjustment range for Horizontal spindles (axial) | 40mm (1.6") | |

| Length of the Infeed Straightening Table | 0.8M (32") | |

| Clutch Roll on 1st top Infeed Roll | Included | |

| Digital Readout and Quick Set to Main guide & Infeed Rolls(Btm Head Cut-table) | Included | |

| Quick Set Setworks on Near Side Head(s) & Top Head(s) (Radial Set) | optional | |

| Mechanical Digital Readouts for the Spindles, Top Head Chip Breakers | Included | Extra Insulation with Steel Punched Sheet Steel Ineterior |

| Full Sound and Safety Enclosure w/ Strobe-free Lighting | Included | |

| Motorized vertical adjustment of Feed Beam with Top Feed Rolls | Included | |

| Pneumatic Lateral Pressure Roller Systems on Infeed & opposite first right spindle | Included | |

| Extra HD Chainless Cardan Shaft Feed System w/ExHD Gearboxes | Included | optional on all Axis and SmartSet Controls as noted Below optional |

| Diameter of Dust Hood for Vertical Spindles | Ø200mm (7.9") | |

| Diameter of Dust Hood for Horizontal Spindles | Ø230mm (9.1") | |

● All specifications, dimensions and design characteristics are subject to change without notice.

| OPTIONAL EQUIPMENT : | |

| Straight or Profile Jointers on any heads | Left (Opposite) Hand Feed |

| Remote Jointer Control | Cutterhead Lift Off Crane |

| Tilting Side Heads - to 45 degrees | Rip Saw Section with up to 56kw (75HP) |

| Split Top Head Pressure Shoes | Additional Quick Set Setworks on any desired Cutterhead Axis |

| Directly Opposed Side Heads | |