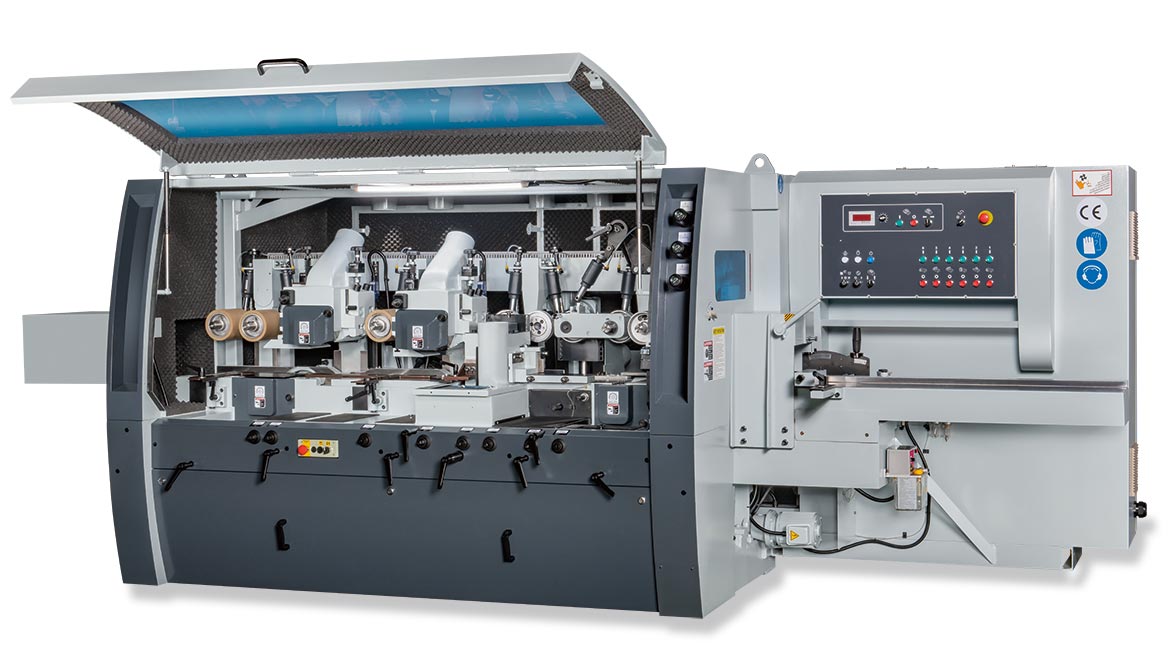

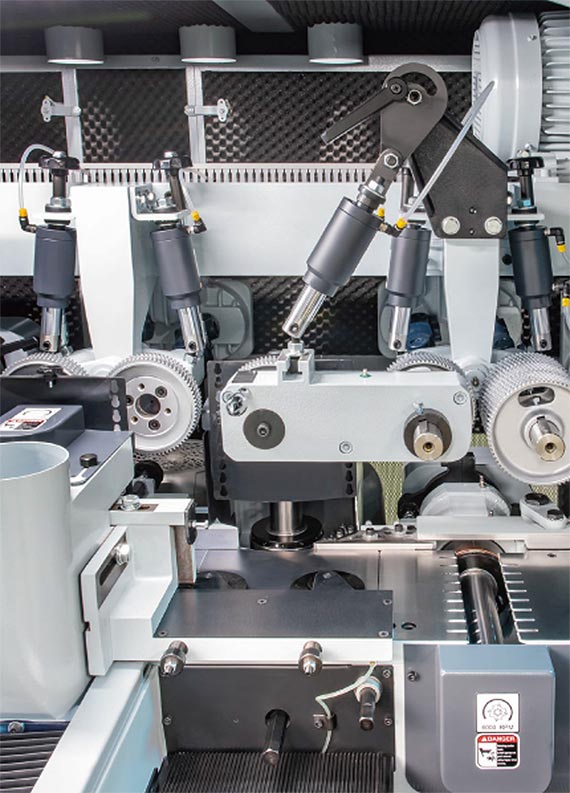

EADERMAC's wide variety of 4-side moulders have all the very latest technology for increased productivity. These heavy duty moulders are designed to provide fast feed speeds and high accuracy. The machines are precision manufactured by our highly skilled technicians - plus Leadermac service, training, and moulding know-how is offered. No matter what your moulding jobs call for, there is a Leadermac 4-side moulder that's right for you.

(Other configurations available on request)

Leadership Through Performance and Reliability

LEADERMAC's wide variety of 4-side moulders have all the very latest technology for increased productivity, product quality & reliability. These Heavy Duty Moulders are designed to provide fast cutting speeds and highest quality & accuracy. These machines are precision manufactured by our highly skilled technicians - plus Leadermac service, training, and moulding know-how is offered with each moulder. No matter what your moulding jobs call for, there is a Leadermac 4-side moulder that's right for you.

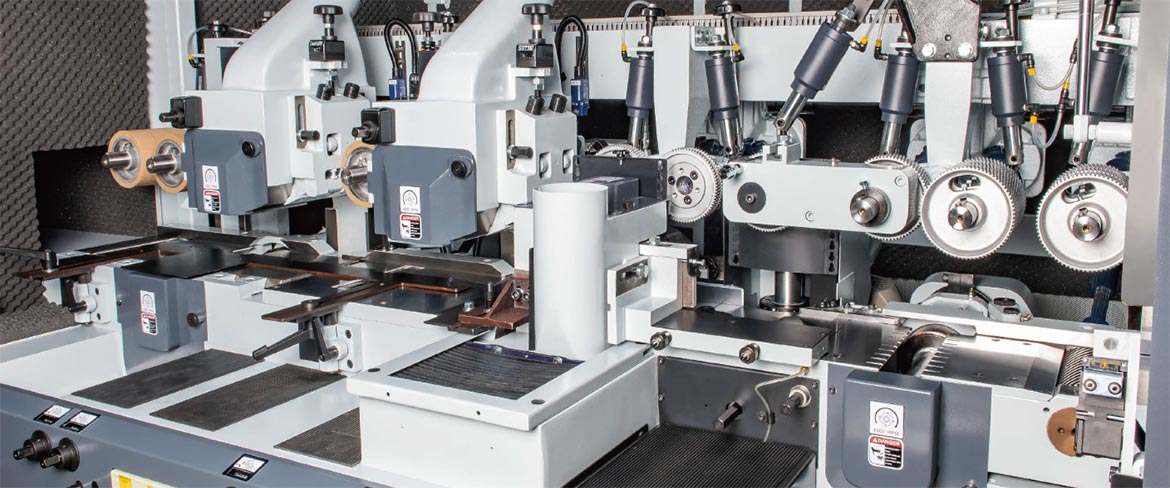

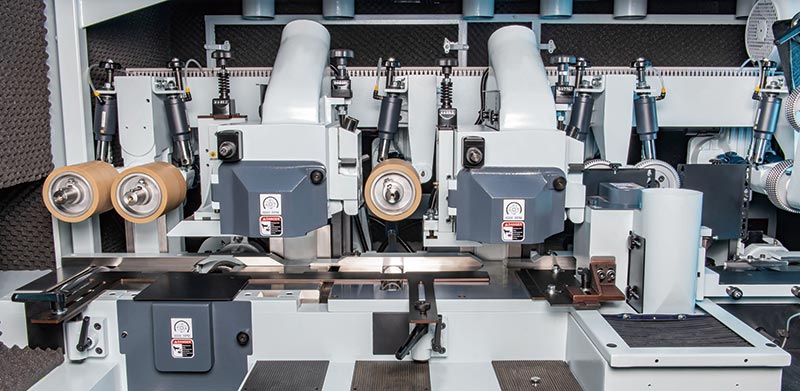

The entire Cast Iron – Chromed Infeed table is normalization heat treated for maximum stability. Infeed Table & Fence adjustment is quickly accomplished by means of a quick-setting levers.

This device permits the feeding of short stocks with a minimum length of 8". The short stock feeder is driven by a gear drive unit for a powerful and smooth effect.

The position of the Top Head Chip Breakers and Pressure Plates are accurately displayed by digital counters. This increases cutting stability.

Powered Infeed Bottom Roller (actually More Powered Top & Bottom Feed Rolls than almost all of our competition.) The smooth initial feeding of the stock is achieved by means of the independently powered infeed rollers.

The short stock powered feed mechanism provides added smoothness for short workpiece feeding. The auxiliary feed rollers are power driven for effortless feeding effect, and are quick-liftable for convenient cutterhead change or setup.

Touch Screen Control.

Touch Screen Control

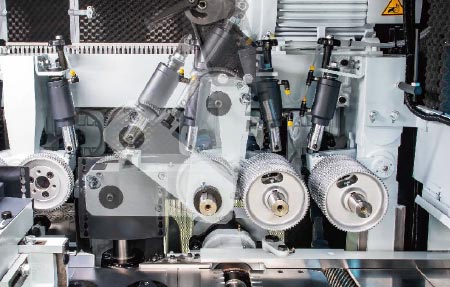

The speed is VFD Inverter controlled, and all electrical components meet CE, UL & CSA standards.

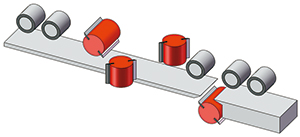

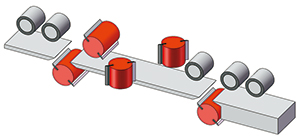

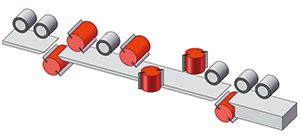

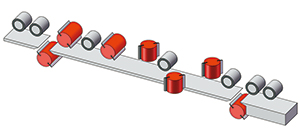

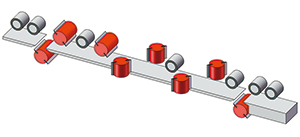

A Wide Range of Spindle Configurations (other configurations available on request)

LMC-423 4-SPINDLE

LMC-523 5-SPINDLE

LMC-623 6-SPINDLE

LMC-723 7-SPINDLE

LMC-823 8-SPINDLE

| STANDARD EQUIPMENT: | LMC-423C to LMC-823C | 4 Head to 8 Heads |

| Standard Machine Specs | Optional Specs | |

| Working Width (at a tool cutting circle of 163mm) | 15-230mm (0.59"-9.1") | to 240mm, 300mm (9.4", 12" optional) |

| Working Height /Thickness (at a tool cutting circle of 163mm) | 10-150mm (0.39"-6") | to 6mm & to 200mm (to 1/4" & to 8") - optional |

| Number of Spindles, Min-max | 1 to 8 Heads/Spindles | All different types of Spindle Configurations - optional |

| Basic motor Capacity of Feed - Variable Speed Drive | 4KW / 5HP | 5.5KW / 7.5HP or 7.5KW / 10HP - optional |

| Feed Speeds, Infinitely Variable | 6 - 24 m/min (20 - 80 fpm) | |

| Basic Motor Capacity Per Spindle | 7.5KW / 10HP Vert & 11KW/15HP Hor. | up to 18.5KW / 25HP - optional |

| Spindle Speed | 6000 RPM | 7200 RPM - optional |

| Spindle Diameter | 40mm (1.6") | 50mm, 1 1/2", 1 13/16" |

| Tool Cutting Circle, 1st Bottom Spindle, Min-max | 125-160mm (4.9"-6.29") | |

| Tool Cutting Circle, Vertical Spindle(s), Left, Min-max | 112-200mm (4.4"-7.9") | |

| Tool Cutting Circle, Vertical Spindle(s), Right, Min-max | 112-200mm (4.4"-7.9") | |

| Tool Cutting Circle, Horizontal Spindles, Top, Min-max | 112-200mm (4.4"-7.9") | |

| Tool Cutting Circle, Borizontal Spindles, Bottom, Min-max | 112-200mm (4.4"-7.9") | |

| Feed Roll Diameter | 140mm (5.5") | |

| Top Feed Roll Width - Each Roll With Multiples on all Top Shafts | 50mm (2") | |

| Bottom Feed Roll(s) Width | Full Width | |

| Pneumatic Pressure for Feed Rolls, Max | 6 bar (85psi) | |

| Adjustment Range for Infeed Table | 10mm (0.4") | |

| Adjustment Range for Edge-jointing Fence | 10mm (0.4") | |

| Adjustment Range of Vertical Ppindles (axial) | 40mm (1.58") | 80mm (3.14") - optional with setworks if desired |

| Adjustment Range of Horizontal Spindles (axial) | 20mm (0.79") | |

| Length of the Infeed Straightening Table (Bottom Head Cut) | 2M (78.7") | 2.5M or 3M (98" or 120" - optional) |

| Diameter of Dust Hood for Vertical Spindle(s) | 125mm (5") | |

| Diameter of Dust Hood for Horizontal Spindle(s) | 125mm (5") | |

| Chainless Cardan Shaft Feed System w/ HD Gearboxes | Standard | |

| Motorized Vertical Adjustment of Feed Beam | Standard | |

| Lateral Pressure Rollers Opposite First Right Spindle | Spring Tensioned Standard | Pneumatic Tensioned - optional |

| Sectional Radial Lift - Linkage Style Top Head Chipbreakers | Spring Tensioned Standard | Pneumatic Tensioned - optional |

| Mechanical Digital Readouts for the Pressure Shoes & Hold-down Unit | Standard | |

| Mechanical Digital Reaouts on all Spindle Axis | Single - Std. | Dual on Near Side, & Tops - Radial Readouts & Quik Set - optional |

| Central Location of all Lubrication Points Along the Front of the Machine | Standard | |

| Table Lube System | Manual 1 shot | Auto Electronic - Timer Controlled - optional |

| Full Sound and Safety Enclosure | Standard |

* All specifications, dimensions and design characteristics are subject to change without notice.

| SOME OPTIONAL EQUIPMENT: | |

| A Wide Range of Spindle Configurations | Split Top Head Pressure Plates |

| (Other Configurations Available on Request) | Tilting Top Pressure Plates |

| Universal Last Head or Rip Saw Attachment | |