LEADERMAC Platinum series

LEADERMAC's wide variety of 4 side moulders have all the very latest technology for increased productivity. These heavy duty moulders are designed to provide fast cutting speeds and the best accuracy. The machines are precision manufactured by our highly skilled technicians - plus Leadermac service, training, and moulding know-how is offered. No matter what your moulding jobs call for, there is a Leadermac 4 side moulder that's right for you.

Integrating Many Fine Features You've Come to Expect

World Class Moulding Solutions

OUTSTANDING FEATURES:

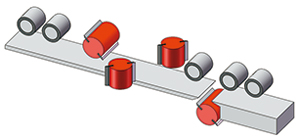

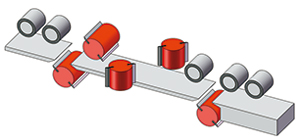

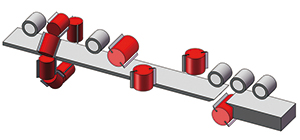

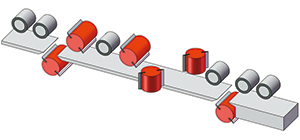

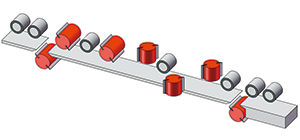

- Standard Machines 4 – 8 Heads (Special Machines from 1 to 8 Heads).

- 230, 260, 300mm (9“, 10.2”, 12” ) Wide x 150, 200mm (6”, 8” ) Thick.

- 1-piece, Cast Iron Machine Frame is specially heat treated for maximum stability and rigidity as standard – wonderful for vibration absorption (for Std. Configuration machines).

- Table Surfaces, hard hard-chrome plated for maximum wear resistance as standard.

- Feed speeds of up to 30mpm (100fpm) are standard with VFD Drive.

- More powered Top & Bottom Feed Rolls then most of our competition.

- Each spindle is driven by an individual motor for powerful machining and easy control.

- Adjustment of each spindle can be easily performed using the front adjustment controls.

- The full safety enclosure serves as a chip guard and helps to reduce noise.

- Pneumatic pressure of the feed rollers can be easily set to provide an outstanding feeding effect. Top Infeed, Midfeed & Outfeed Rolls each have there own pressure settings. Combination Pressure Gauges & Regulators mounted on the Outside of the enclosure support column.