Products

Horizontal Machining Centers

H3 Horizontal Machining Centers

Your No.1 Choice of High Speed, High Precision Machine

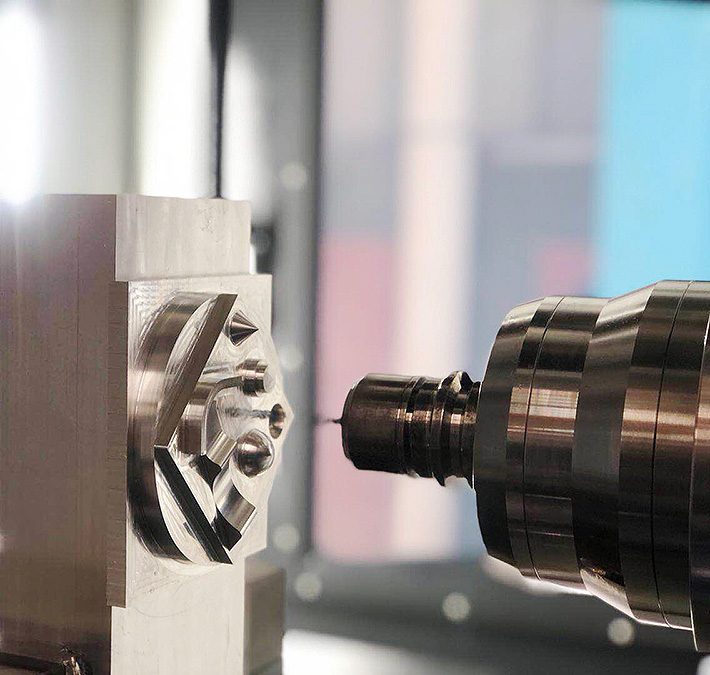

Featuring highly rigid machine structure, the Bors H3 series horizontal machining center is designed with servo motor drive on 3 axis. This machine employs a 24,000rpm built-in type high speed spindle, making the machine ideal for high speed machining for precision parts.

It is equipped with an automatic pallet changer, allowing workpiece loading/unloading to be more convenient and faster.

Outstanding Features :

- Ball screws on 3 axis are equipped with double nuts for resisting heavy load and consistent accuracy.

- Rotary table (B axis) is applicable for multi-side machining.

- Pallet change is fast accomplished in only 10 seconds.

- Twin-pallet change allows for workpiece loading/unloading during the machine is operating

- 3 axis feeds are driven by servo motors.

- BT30, 24,000rpm built-in type high speed spindle.

- BT30, 24 tools disk type machine.

- Rotary table indexing accuracy : 0.001°.

- Table sizes 300 × 300mm.

Application :

- Parts of computer, communication and consumer electronics

- Automotive parts

- Bicycle parts

Stainless steel frame/stainless steel/hard-to-cut material and need to finish the small hole groove. The equipment can meet the difficult-to-cut and high-precision complex workpiece.

| H3 | Traditional Processing mode | |

|---|---|---|

| Machine Tool |  |

|

| Tool |  |

|

| Fixture |  |

|

| Personnel/Maintenance |  |

|

| Loading & Unloading | 10 sec | about 40 sec |