Products

Industrial Applications

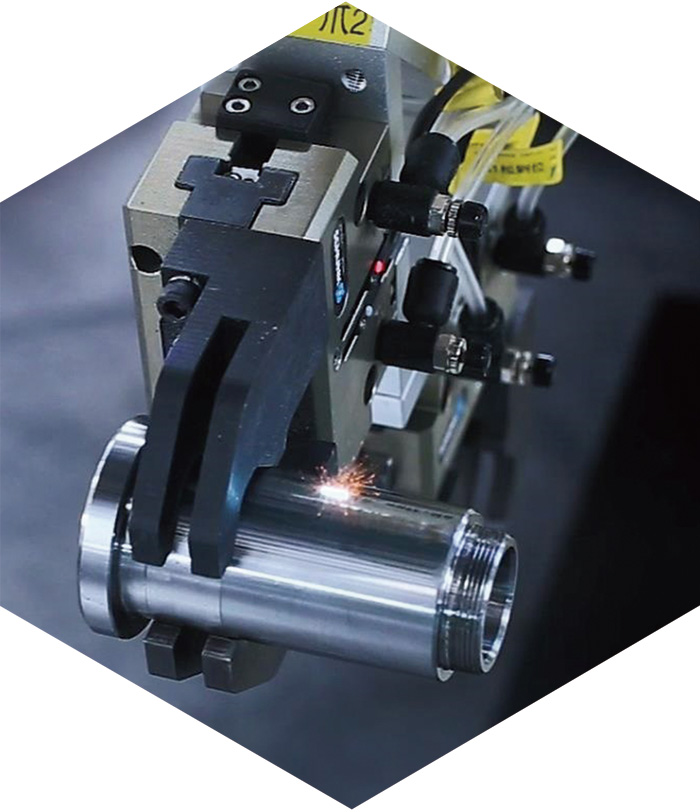

Metal processing

Machine toole and press maching tending applications, as well as plate and pipe welding, compression, and other technical applications, which can be easily achieved.

Automotive Parts

Leantec help customers face the trend of efficiency and safety in the industry and provide maching, measurement and traceability solutions to improve quality and pnoduction efficiency.

Electronic

The Bors arms can complete fast, multiplexing automatic production models, including screw fastening, insertion, spot welding, and other high-precisionprocessing applications.

Food Packaging

Facing the ever-changing needs, Leantec provides digitalized and intelligent solution to maitain and improve food safety togther.

Automation Applications

Smart Factory Solution

BORS Smart Factory Solution provides Smart Machine Box, WiFi Connection Module, and Smart Factory Software (SynFactory) to digitize the equipment and production information. Customers can use these information to analyse the utilization bottleneck

and improve the management method and productivity.

Factory Automation Solution

BORS provides HC Series Controllers, FC Series Controllers, 4-in-1 Servo Driver, and Machine Vision System. Integrating with highly

friendly customization tool, Leantec Factory Automation Solution will help FA makers quickly build their own customized machine to adapt multiple demands of various industries.

Robot Cell

BORS offers various types of Robot arm to help customers achieve automation production line. In addition, Leantec bundles different modules to meet different field requirements and maximize the production efficiency, solving automation

issues in flexible manufacturing cases.

BORS Modular Products

BORS offers common modular components for typical smart factory applications, assisting customers in assembling automation production line effortless and satisfying various application scenarios, and ultimately realizing Industry 4.0 target.