Products

Maglev Moving Column Super Machining Centers

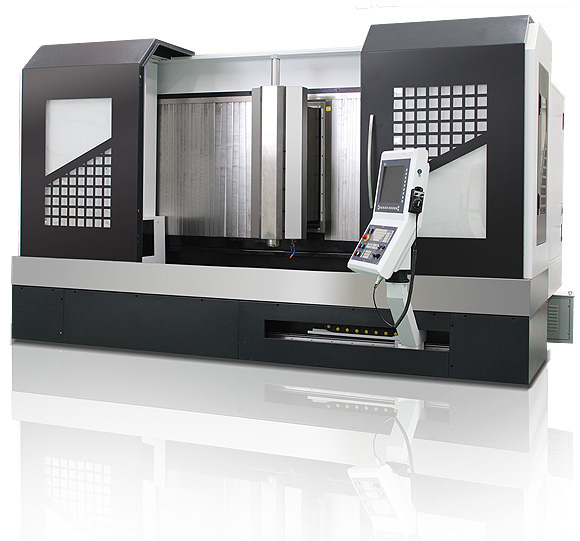

S20 Maglev Moving Column Super Machining Centers

Moving Column Structure / Flexible Machining

The S20 maglev moving column super machining center from Bors features superb design and outstanding performance. This machine is applicable for precision machining for a wide range of parts. From small size parts to large sized parts, from simple to complex parts, the S20 machining center provides high speed, high efficiency machining with extra fine surface finish

Outstanding Features :

- Moving column structure provides flexibility for slender parts machining.

- Granite bed features outstanding dampening capacity and no deformation.

- X, Y, Z-axis are driven by linear motors.

- BT30, 24,000rpm built-in type high-speed spindle.

- BT30, 20 tools disk type magazine.

- Rapid traverse rates on X, Y, Z-axis reach 60m/min.

- Wide range of machining capacity makes the machine suitable for machining from small sized to large sized workpiece.

Application :

- Slender parts for aerospace industry

- Aluminum parts for automotive

- Metal frame of TV set

- Root parts and satellite antenna

Combines Several Patents In One:

ZL2015208488193

ZL2015107162251

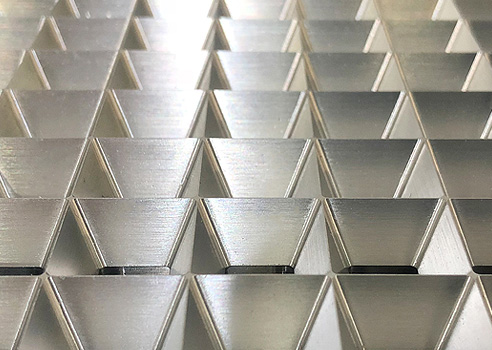

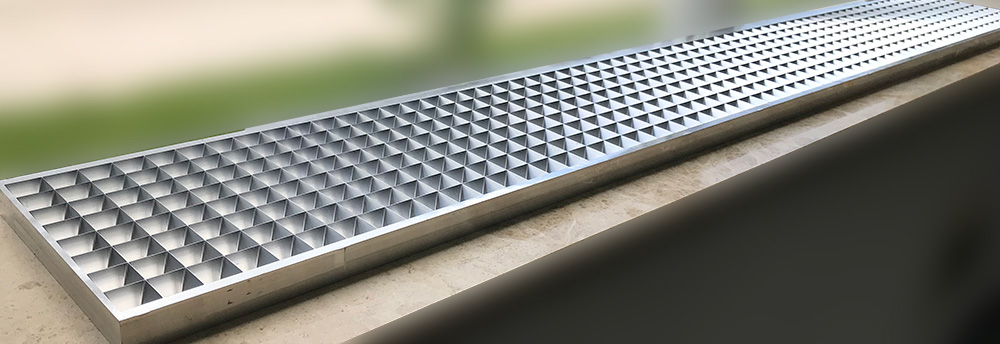

Battery Box (Aluminum)

For machining slender products, this machine willfully present its superb features of high positioning accuracy, high speed and maximum stability.Satellite Antenna (Aluminum)

This machine S20 can fully satisfy the accuracy requirements in machining of long flat workpiece with consistent accuracy.

This helps to upgrade product yield rate.