Products

Maglev small double column machining centers

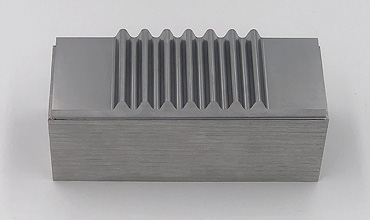

S5/S8 High speed machining center

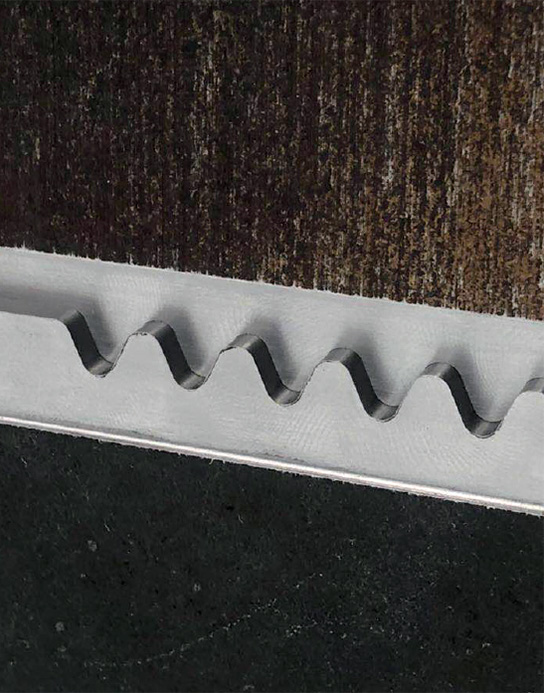

High Speed Machining! / Surface Roughness RA0.02μm

Bors S5/S8 series are high speed machining centers. The design feature is to enhance “Milling instead of grinding”. The machined surface roughness can reach Ra0.025μm, thus significantly saving grinding and polishing time. In addition, it also can increase the product yield rate by 5%.

Outstanding Features :

- Create mirror effect surface finish.

- Product yield rate is increased by 5%.

- Granite bed.

- X, Y, Z-axis are driven by linear motors.

- BT30 20 tools disk type magazine.

- 30,000rpm built-in type high speed spindle.

- Rapid traverse rates on X, Y, Z-axis up to 60M/min.

Application :

- Parts of computer, communication and consumer electronics

- High precision molds

- Automotive parts

Combines Several Patents In One :

- ZL2015304229212

- ZL2015304228188

- ZL2015208483698

- ZL2015208488367

- ZL2016100696163

- ZL2016100697383