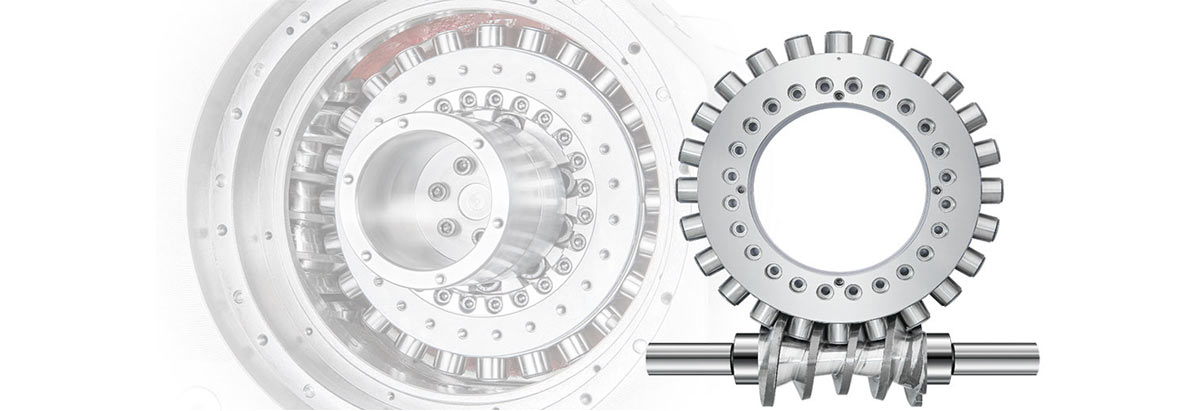

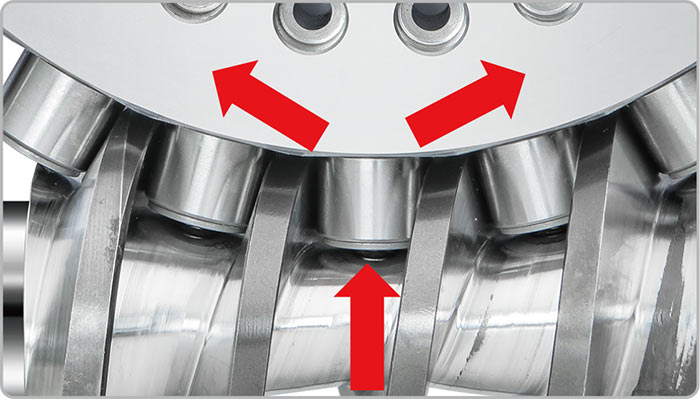

Preload adjustment can completely eliminate the engagement of roller and cam shaft to reach zero backlash and to ensure at least 4 rollers contacting cam shaft during rotation for high rigidity performance.

Core Technology

Core Technology

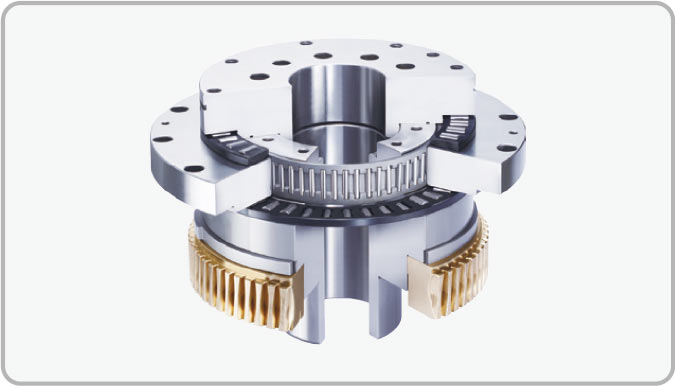

Zero-Backlash Roller Gear Cam Drive

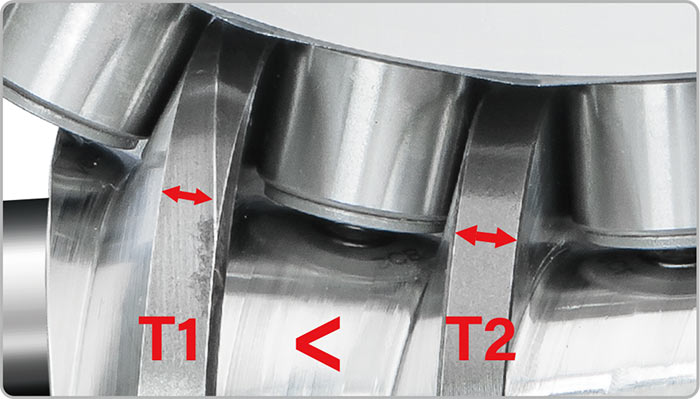

Dual Lead Cam Shaft Mechanism

Dual Lead cam shaft design (T1 < T2) ensures the meshing performance between rollers and the cam shaft, which significantly reduces vibration and improves surface processing accuracy.

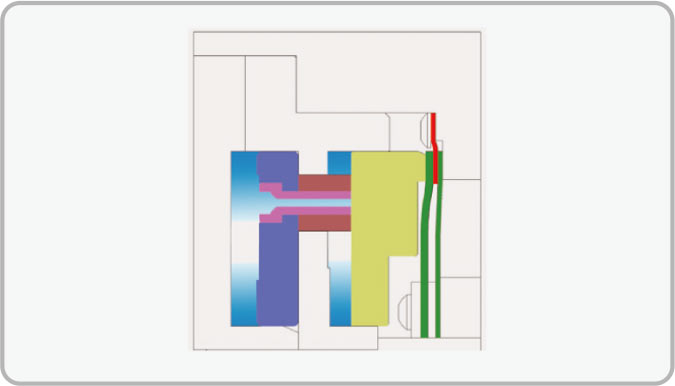

Reliable Clamping Force

High Rigidity Consolidated Spindle

Hydraulic Model:

Special design of drum brake system.

Pneumatic Model:

exclusive patented dual pistons design.

YRT bearing integrated in consolidated spindle with least separate elements & premium rigidity.

Strict Insoection Norm

◄ Accuracy Inspection upon ISO 230-2 international norm is operated with 5 continuous runs in clockwise and counterclockwise test.