Core Technology

Core Technology

Direct Drive Motor DDM series

Built-in Torque Motor for Direct Drive

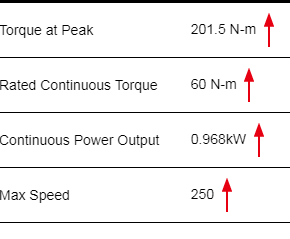

- - Built-in torque motor for direct drive, max speed 250rpm.

- - Super low inertia, high efficient gain loop response.

- - High acceleration and deceleration, 0- 180 degree positioning in 0.2 sec.

- - Zero backlash, mechanical wear-free and least friction.

- - High- end European optical encoder as standard equipment.

- - Excellent accuracy guarantee- 20 sec for positioning, 4 sec for repeatability.

- - ISO 230-2 norm applied as standard inspection.

- - Consolidated main body, all mounting interface are integrated onto the cartridge. Premium rigidity retained.

- - IP65 water proof with European adherent electrical connection.

- - Thermal detection as standard feature.

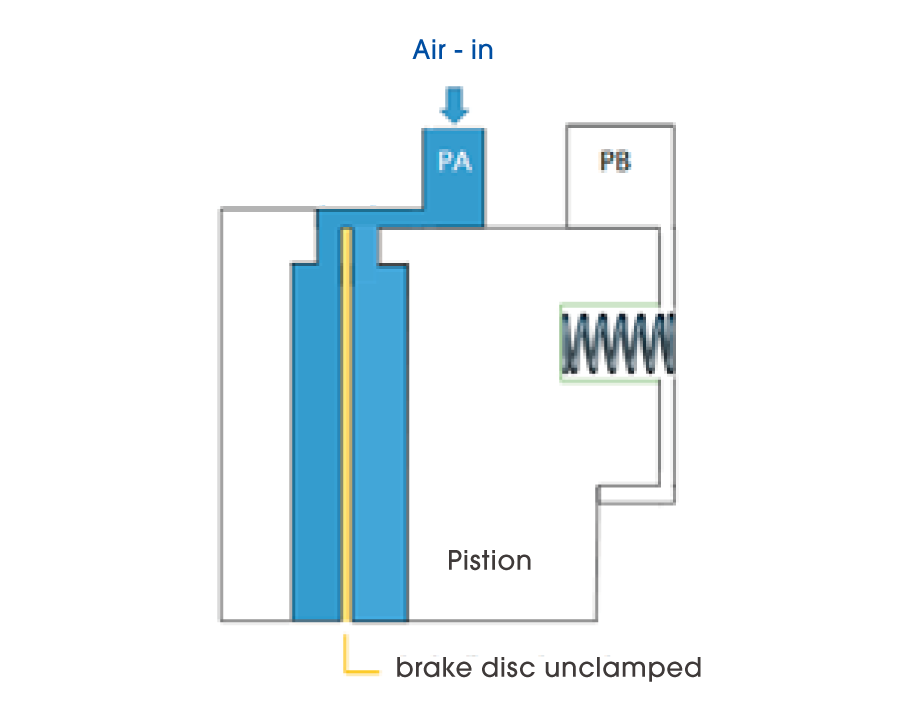

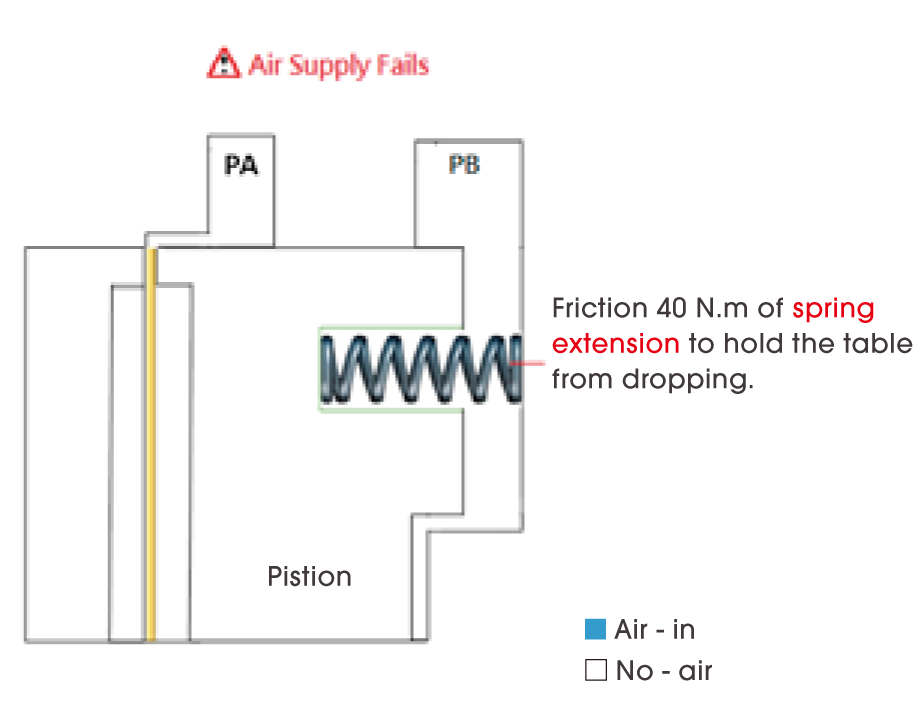

- - Safe parts holding design during power failure.

- - Noise- reducing, easy maintenance, free from oil waste.

- - Compact structure for flexible working envelope.

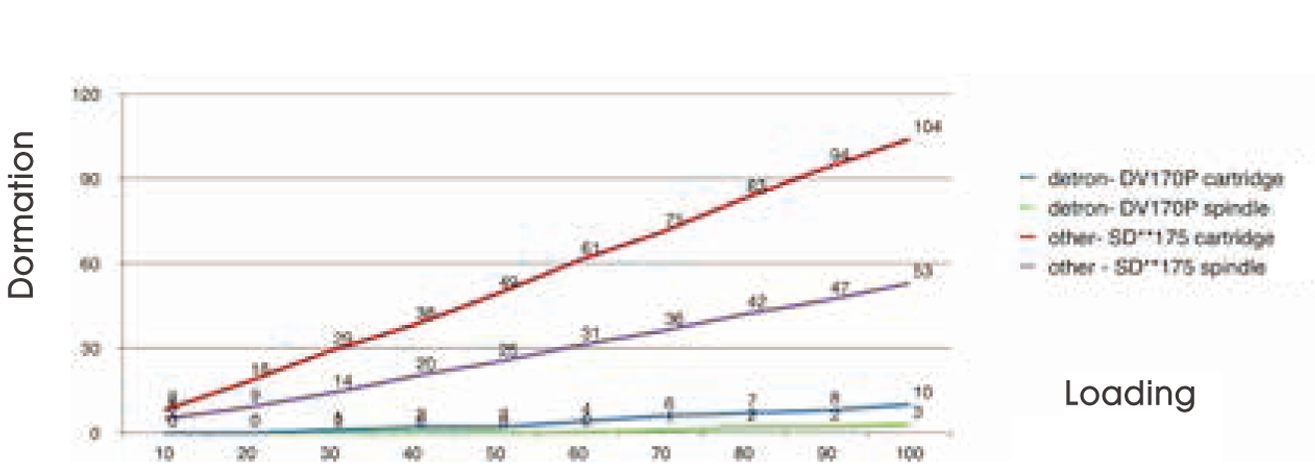

Core Technology- High Speed and Precision

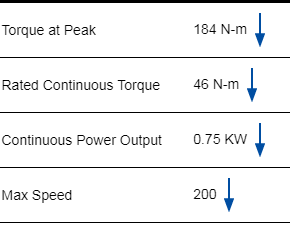

Higher Speed and Torque Performance

Table Ø 170mm model as example

detron

Others

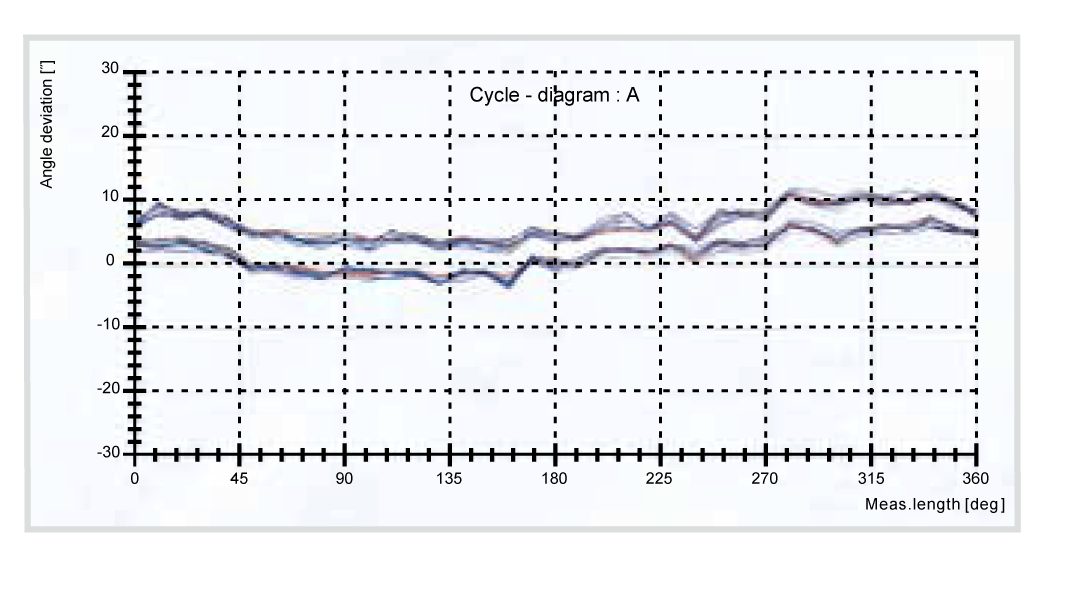

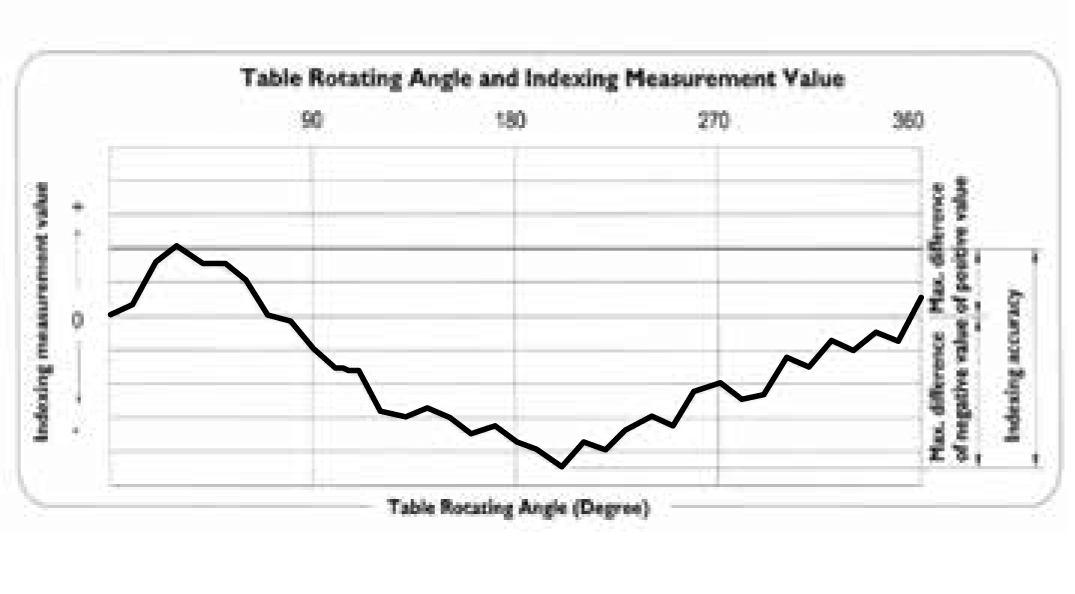

Strict Inspection Norm

Table Ø 170mm model as example

detron

ISO 230-2 (JIS B6192)

Accuracy Inspection upon ISO 230-2 international norm is operated with 5 continuous runs in clockwise and counterclockwise test.

Others

JIS B6330

Simplified inspection norm without number of laps indicated.

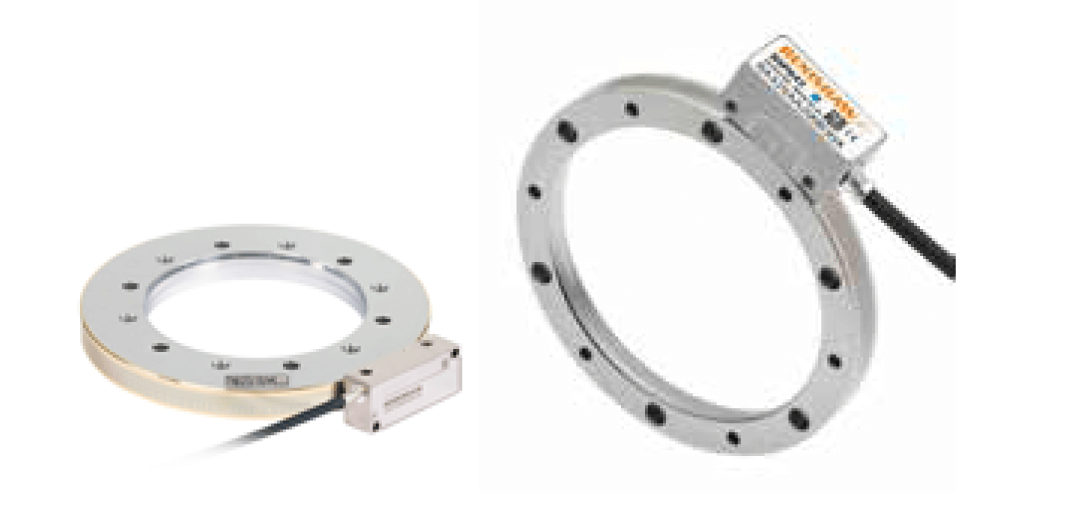

European High End Optical Encoder Applied

detron

European Heidenhain or Renishaw are standard attachment for all detron DDM series. High resolution by ±2.5 secs.

Others

Economic encoder by ±10 secs is applied, non- CNC purpose application.

Core Technology - High Rigidity

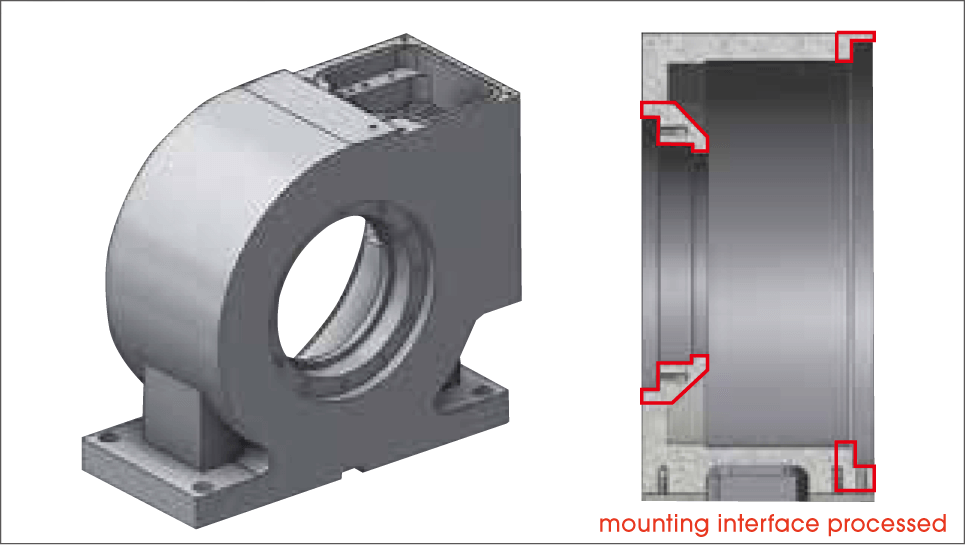

Main Cartridge Structure

detron

- - Consolidated main cartridge with spindle mounting interface reserved.

- - Least isolated components, accumulated error reduced.

- - Excellent rigidity dynamic balance while high speed operation, low inertia and run-out concern.

- - Closer distance between optical encoder and bearing for higher positioning detection.

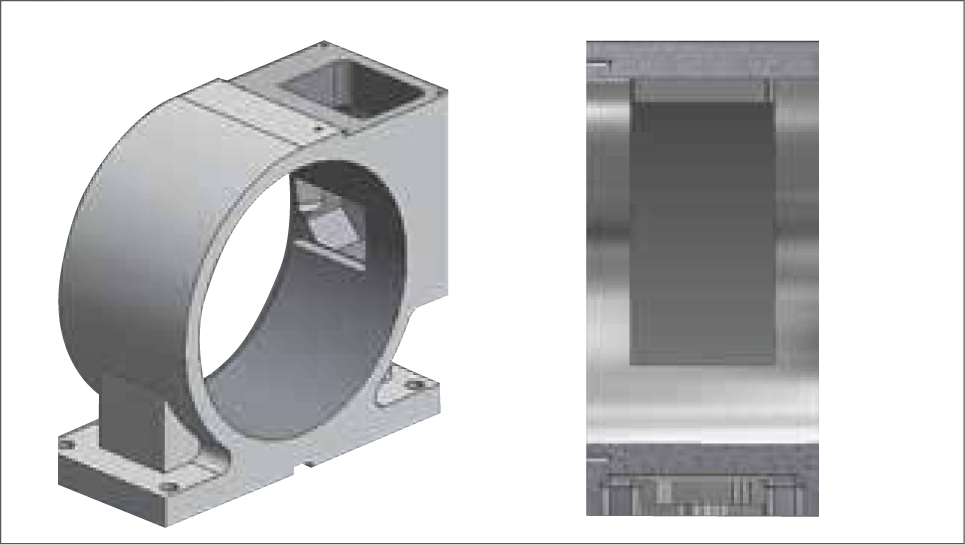

Others

- - Weak and hollow cartridge without mounting interface reserved. Spindle is installed by isolated flanges.

- - Isolated parts caused more accumulated errors.

- - Instable rigidity and deformation, mass inertia, low loading capability. Not recommended for high speed processing.

- - Longer distance between encoder and bearing, positioning detection is limited.

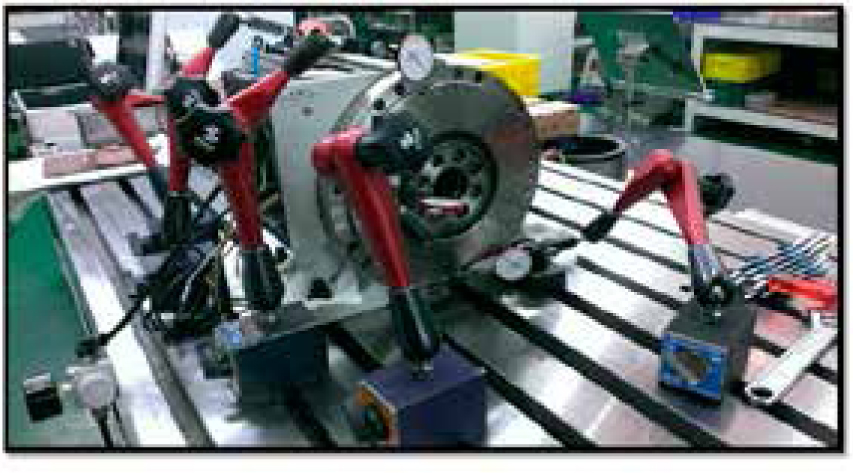

practical test

practical test Rigidity Experiment Analysis

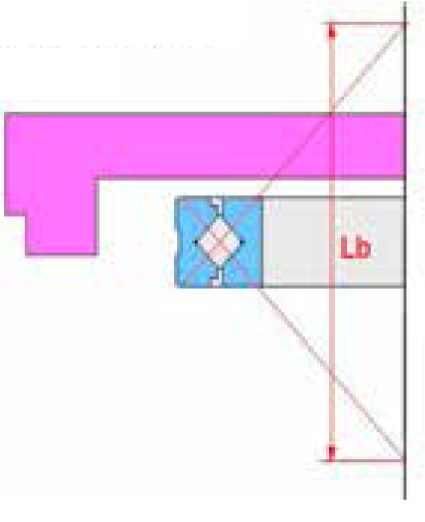

Spindle Bearing

detron

Cross Roller Bearing

momentLbis longer thanLc, better loading performance.

Cross roller bearing with high capability of axial and radial loading. Better moment to ensure dynamic rigidity.

Others

Taper Roller Bearing

momentLcis shorter thanLb, lower loading capacity.

Low cost taper roller bearing, poor moment and less loading effect.

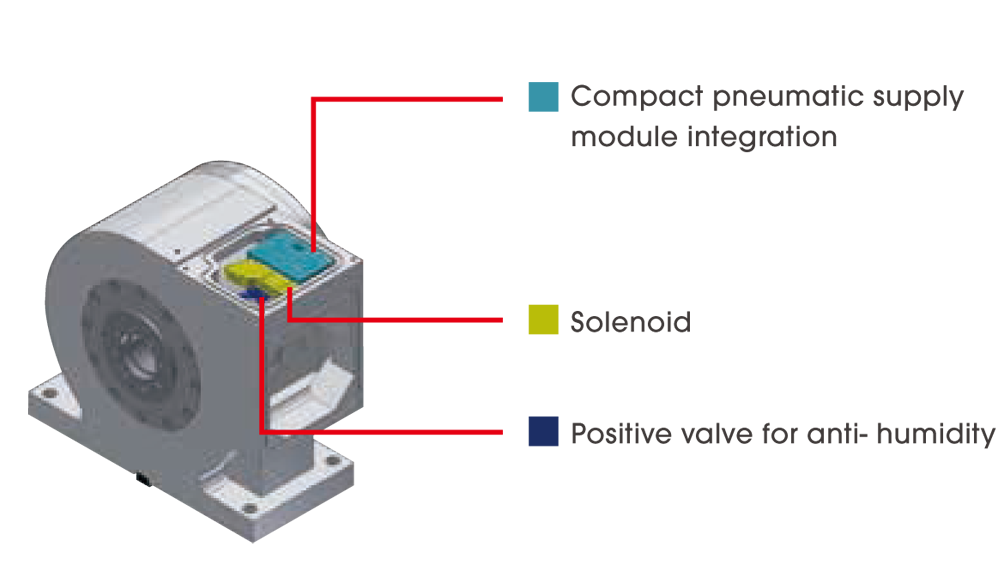

Guarantee for Thorough Protection

Chip and Water Proof

detron

- - European adherent connector guarantees safe water proof, signal/ power cable/ pneumatic tube are all integrated in 1 compact pipeline.

- - All cables are shielded by anti- erosion pipe and the outer lattice prevents breakage by cutting chips.

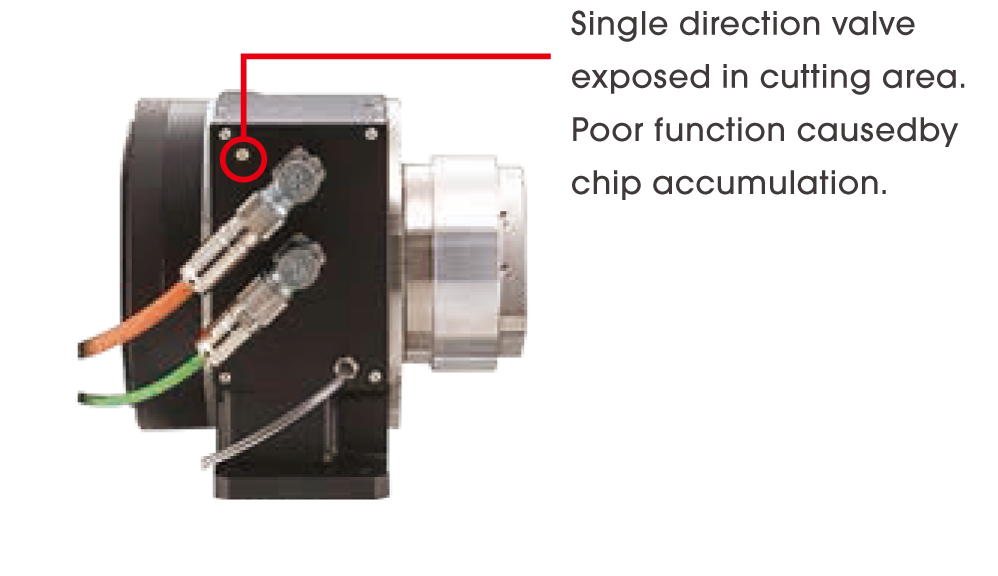

Others

- - Cables terminated in low cost plug connectors. Isolated electronic and pneumatic pipelines are randomly arranged.

- - Poor pipe material. Erosion and chip cut concern on nylon pipes. High risk by frequent break-down.

detron

Others

Brake in Various Condition

Table in Operation

Table Positions

Power Failure