|

| SRU-2040 (Plunge Grinding) |

|

|

|

| A Combination of Technology and Precision |

| Advanced CNC Control |

The machine is equipped with the latest CNC control with teach-in programming and is easy to operate.

Machining programs are automatically generated through graphic dialog. This greatly saves on preparation time while increasing efficiency. |

|

|

|

| |

|

|

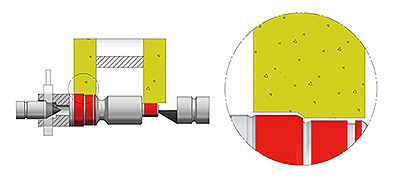

Grinding Wheel Spindle Supported by Hydro-static Bearing

The grinding wheel spindle is precision machined from Nickel Chromolybedenum alloy steel (SNCM-220). It is supported by hydro-static bearing, which greatly upgrades the spindle running stability while reducing temperature growth to a minimum.  |

|

|

| Plunge Grinding Grinding Examples |

|

|

| |

|

| |

| SPECIFICATIONS |

SRU-2040 |

Capacity

|

Distance between centers

|

420 mm

|

Swivel over table

|

200 mm

|

Max. load of centers

|

80 kg

|

| Max. external grinding diameter |

190 mm |

| Roundness |

0.8 μ |

| Machine Position Accuracy |

1 μ |

| Wheel head |

¡@ |

| Swivel angle |

±30° |

| Wheel O.D. x width x I.D. |

405 mm x MAX 70 mm x 127 mm |

| Wheel head travel |

180 mm |

| Max. travel |

180 mm |

| Min. setting unit |

0.001 mm |

| Rapid traverse rate |

6 m/min |

| Grinding feed rate |

0.01-6000 mm/min |

Table

|

Swivel angle

|

-3°¡ã+12° |

Max. travel

|

420 mm |

Rapid traverse rate

|

8 m/min |

Min. setting unit

|

0.001 mm |

| Grinding feed rate |

0.01-6000 mm/min+ |

Work spindle head

|

Spindle motor

|

SERVO MOTOR |

| Transmission type |

fixed / chuck |

Swivel angle

|

90°¡ã30° |

| Center taper |

MT4 |

Tailstock

|

Travel

|

20 mm |

| Center taper |

MT4 |

Motor

|

¡@ |

| Drive motor |

X-axis 1 kw |

| Z-axis 1.5 kw |

Wheel spindle

|

5HP |

Workload spindle

|

0.75 kw |

Hydraulic pump

|

2HP |

| Coolant pump |

1/4HP |

Machine dimensions

|

2730 x2500 x 1980 mm |

Net weight

|

3350 kg |

| Gross weight |

3600 kg |

|

| |

|

| |

| Standard Accessories |

- Grinding Wheel and flange x 1 set

- Diamond tool holde x 1 set

- Tool box x 1 set

- Carbide tipped work centers x 2 pcs

- Coolant equipment x 1 set

- Hydraulic pump with tank x 1 set

- Work lamp x 1 set

|

|

| ¡@ |

| Optional Accessories |

- Internal grinding attachment (including 3-jaw chuck anode spindle)

- Diamond tool holder for internal and external grinding wheel dressing (upward open type)

- Diamond tool holder (tailstock mounted type)

- Diamond tool holder for internal and external grinding wheel (sideward open type)

- Angle trimming device

- Radius trimming device

- Cam locked driving dogs

- Work steady rest

- 2-point steady rest

- 3-point steady rest

- Adjustable 3-jaw scroll chuck

- Adjustable 4-lock chuck

- Magnetic coolant separator

- Magnet filter with paper

- Wheel balancing stand and arbor

- Renishaw end face touch probe

- O.D. measuring device- MARPOSS / TOKYO SEIMITSU

|

|

| ¡@ |

|