|

|

|

|

|

|

|

|

Advanced CNC control provides powerful function and high efficiency. |

|

Teach-in operation control for easy operation. |

|

Servomotor drives on 4 axes assure high speed motions and high positioning accuracy. |

|

Regulating wheel is driven by a servomotor, providing variable speed change. |

|

The structural parts are manufactured from high quality cast iron, heat treated and stress relieved for maximum material stability without deformation. |

|

The grinding wheel spindle and the regulating wheel spindle are precision machined from Nickel Chromolybedenum alloy steel (SNCM-220). Both spindles are subject to various heat treatments, making the machine ideal for heavy duty machining and high precision grinding. |

|

The feed screw employs high precision ball screws, normalized and high frequency heat treated for maximum wear resistance. |

|

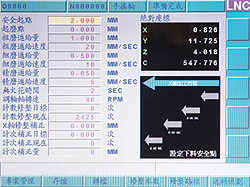

| GRINDING DISPLAY |

| This function provides feed parameter settings on X-axis. It provides various settings, including safety point setting to avoid bumping against tool during loading or unloading workpiece, grinding start point setting, feed amount setting for coarse, fine and finish grinding, feed speed setting for coarse, fine and finish grinding, non-sparkling time setting, regulation wheel spindle speed setting, desired compensation parameter setting on X-axis before and after dressing during automatic grinding operation, desired compensation parameter setting on X-axis to meet the wearing condition of the grinding wheel during automatic grinding operation. |

|

|

|

| DRESSING PARAMETERS DISPLAY |

| This function is used for setting the desired dressing parameters. It provides various settings, including Z-axis retreat distance setting once dressing finished, dressing amount each time, dressing speed, dressing start point and dressing times required. |

|

|

|

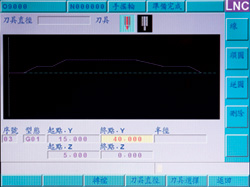

| DRESSING PATH DISPLAY |

| This function provides planing for profile dressing path. It allows for tool selection according to various types of diamond dresser. In addition, it permits operator to input the dressing path according to workpiece sizes, and automatically generates NC path. This means the operator may directly define the workpiece profile on the controller, and then the corresponding NC path programs will be generated directly. |

|

|

| SPECIFICATIONS |

SRC-18S (1~7 Axis) |

| Grinding Wheel¡@ |

| Standard

grinding range (Dia.) |

Ø1∼Ø80 mm |

| Capacity

increases with special arrangement |

Ø40∼Ø150 mm |

| Grinding

wheel size (O.D. x width x I.D.) |

Ø455 x 205 x

Ø228.6 |

| Grinding

wheel speed |

1260 R.P.M. |

| Grinding

wheel motor |

20 HP |

| Regulating Wheel¡@ |

| Regulating wheel size (O.D. x width x I.D.) |

Ø255 x 205 x

Ø111.2 |

| Regulating wheel speed |

10∼300

R.P.M.(Variable) |

| Regulating wheel motor / S series |

2.2 KW servo

motor |

| Regulating wheel tilt angle |

+5º∼-3º |

| Regulating wheel swivel

angle |

±5º |

| Servomotor Motors¡@ |

| Dressing

Servomotor |

Z 750W / Y 750W |

| Infeed

Servomotor |

X 1.5KW |

| Drive Motors¡@ |

| Hydraulic pump motor |

1 HP x 4P |

| Coolant

pump motor |

1/4 HP x 2P |

| Machine Dimensions |

2200 x 1840 x 1530 mm |

| Net

weight |

3500 kgs |

| Gross

weight |

3800 kgs |

| Packing

dimensions |

2320 x 2650 x

2200 mm |

| Standard Accessories |

| . |

- Regulating wheel and flange *1 set (mounted on machine)

- Grinding wheel and flange *1 set (mounted on machine)

- Infeed work rest and carbide blade *1 set

- Thrufeed work rest and carbide blade *1 set

- Standard electric equipment *1 set (mounted on machine)

- Oil tank *1 set (incl. oil cooling fan)

- Standard coolant system *1 set

- Diamond tools *2 pcs (mounted on machine)

- Work lamp *1 set (mounted on machine)

- Tool box and kits *1 set

|

| Optional Accessories |

| . |

- Wheel balancing stand and arbor

- Automatic infeed attachment

- Manual feeder for infeed grinding (up and down)

- Hydraulic work ejector (infeed grinding)

- Automatic loading attachment (thrufeed grinding)(Ø5-20mm, L100-600mm)

- Automatic feeder for thrufeed grinding (hopper type)(Ø2-8mm, L50-180mm)

- Automatic unloading attachment (thrufeed grinding)

- Supporter for long bar grinding

- Profile grinding attachment

- Magnetic coolant separator

- Coolant separator with paper filter

- Hydrocyclone coolant separator

- Auto. loading and unloading attachment (infeed grinding)

- Vibratory feeder (thrufeed grinding)

- Large work rest (thrufeed grinding)

|

|

|

|

|

|

|

|