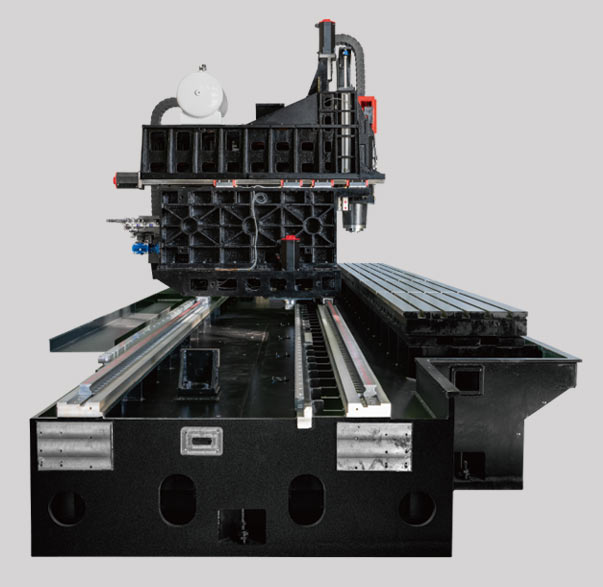

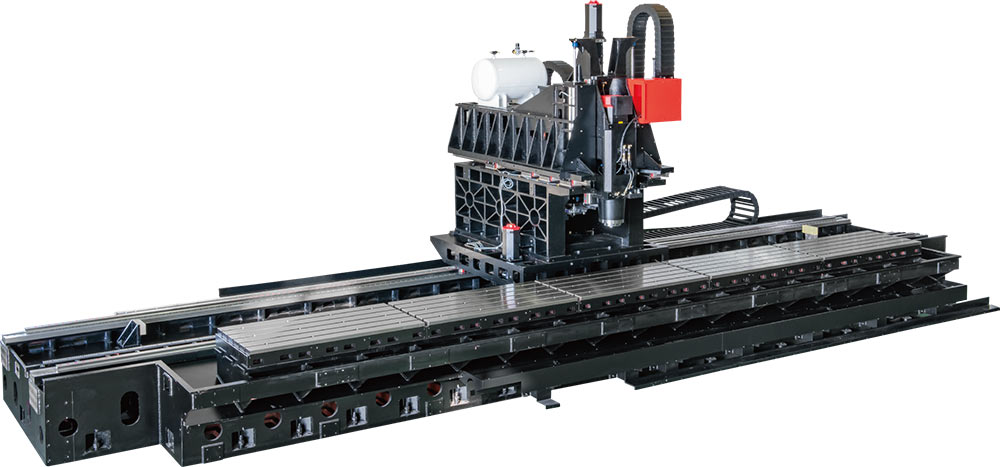

HK-456L

(X-axis travel 4150 mm)

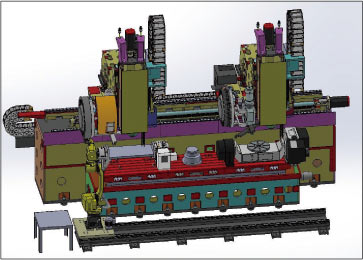

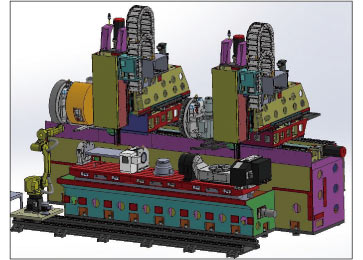

HK-576L

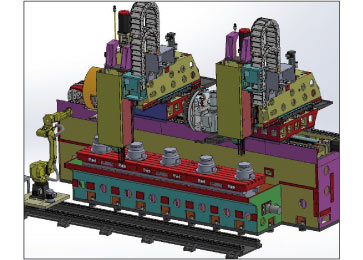

VERSATILE MACHINING APPLICATIONS

This machine is designed specifically for machining long workpieces. In addition, it is also ideal for other types of machining such as multi-section machining and 4th/5th axis machining.

HK-876L