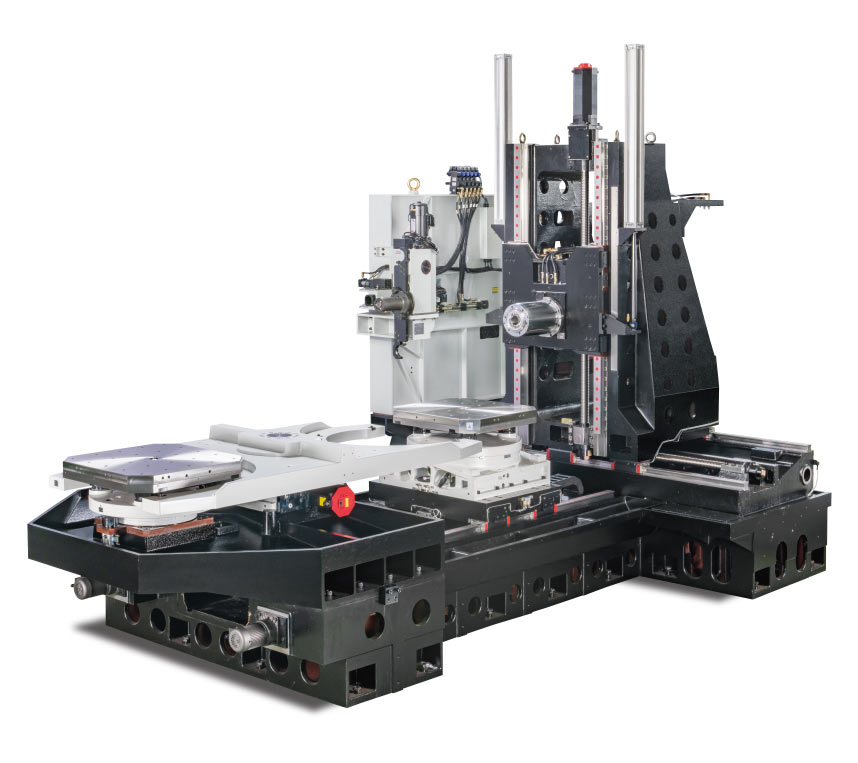

The Heake Horizontal Machining Center features a highly rigid machine structure, enabling it to present exceptional machining stability and accuracy, especially in high speed machining. Three axes are mounted with linear guideways, traveling column design, and automatic pallet change to provide a dramatic increase in machining efficiency. The LH series is equipped with a Fanuc controller in combination with the use of Heake self-developed software functions, making machine operation and management more convenient.

LH-800(A) WITH TWIN PALLETS

HK-LH500(A)

- Table sizes 500 x 500mm

- X, Y, Z-axis travel 800 x 750 x 800mm

- Rapid traverse rates on X, Y, Z-axis 50m/min

- Traveling column

- Twin swing type automatic pallet change (optional)

- B-axis indexing degree 0.001° (1° optional)

- Fully enclosed splash guard

- Max. table load 650kg (single pallet)

HK-LH630(A)

- Table sizes 630 x 630mm

- X, Y, Z-axis travel 1000 x 9000 x 10000mm

- Rapid traverse rates on X, Y, Z-axis 40m/min

- Traveling column

- Twin swing type automatic pallet change (optional)

- B-axis indexing degree 0.001° (1° optional)

- Fully enclosed splash guard

- Max. table load 650kg (single pallet)

HK-LH800(A)

- Table sizes 800 x 800mm

- X, Y, Z-axis travel 1500 x 1100 x 1100mm

- Rapid traverse rates on X, Y, Z-axis 24/30m/min

- Traveling column

- Twin swing type automatic pallet change (optional)

- B-axis indexing degree 0.001° (1° optional)

- Fully enclosed splash guard

- Max. table load 2200kg (single pallet)

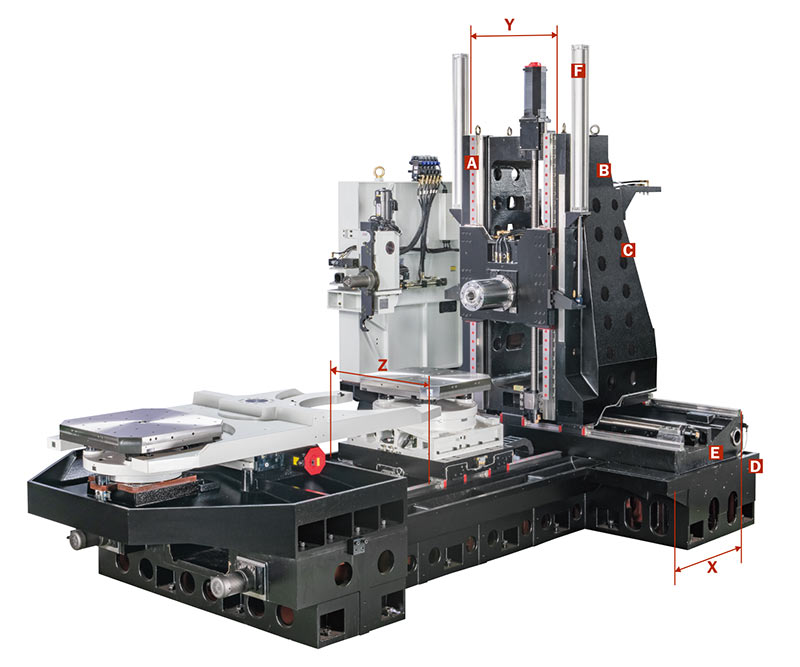

OPTIMIZED STRUCTURE DESIGN

A Perfect presentation of Structural Rigidity and Dynamic Stability

- Box type structure design combined with internal ribbing to achieve outstanding rigidity and deformation free performance.

- One-piece fabricated base provides a solid support for the entire machine.

- Traveling column structure effectively enhances operation efficiency.

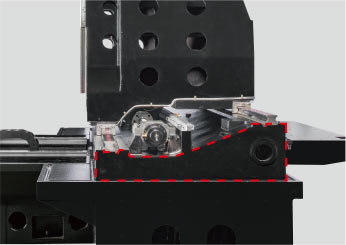

- Linear guideways are deployed on the step structure of X-axis for higher cutting stability.

- X, Y, Z-axes are all mounted with roller type linear guideways with outstanding heavy loading capacity.

- Chip augers are equipped at both sides of the base, allowing for the removal of chips immediately to fast travel, as well as stable and smooth vertical movement.

- Chip augers are equipped at both sides of the base, allowing for the removal of chips immediately during machining.

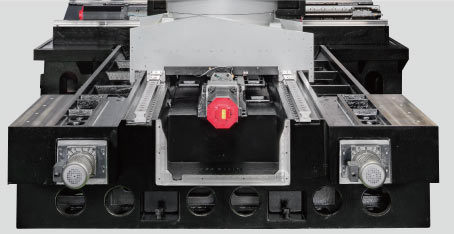

TWIN CHIP AUGERS

- There is one each of chip auger mounted at the right and left side of the base, which can deliver chips generated during cutting to the chip conveyor at the back side of the machine.

- The chip augers can prevent thermal effects that occur due to chip accumulation and keep the machine interior clean at all times.

MACHINE STRUCTURE OF LH-800 (A)

- The massive base and robust column combined with internal ribbing ensure lifetime deformation free performance, while exhibiting outstanding rigidity and stability.