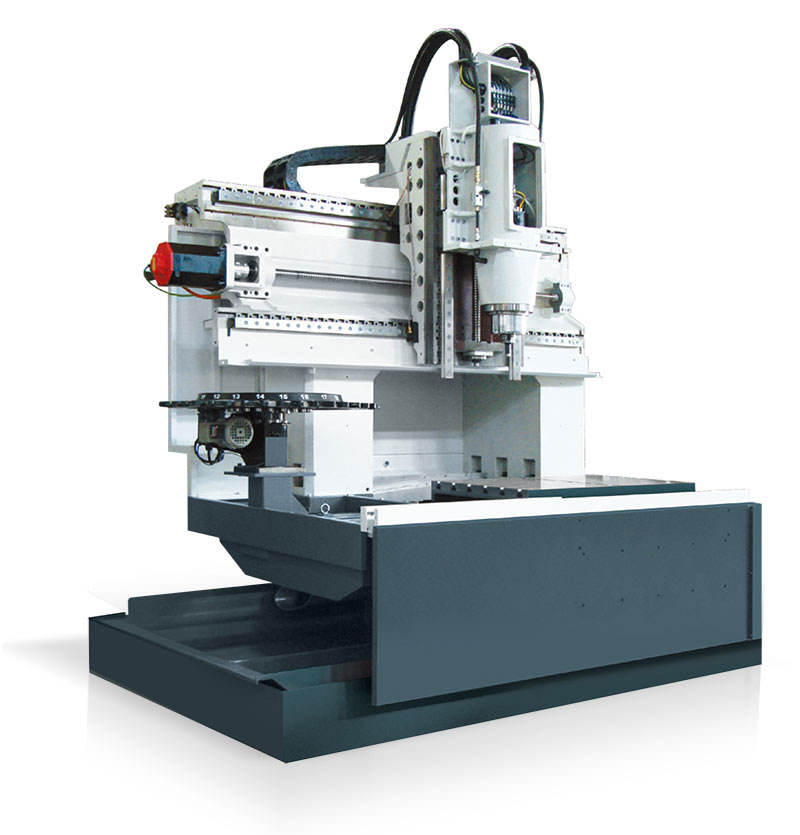

High Speed Bridge Machining Center LV-850

Feature

- Designed for mold making and precision parts machining.

- Emphasized rigidity structure and integration of mechanical & electrical, to upmost customer's productive efficiency.

- Unique single-piece casting for the double column & cross rail design.

- Column size up to 600 x 330 mm to strengthen stability while speed cutting.

Bridge Type Structure by One-piece Constructed

- Double column structure and high rigidity design, can provide mold processing industry with High Precision and High Efficiency of The Processing Performance, superior cutting rigidity and more humanized mode of operation and machine stability, can enhance the efficiency of the operator.

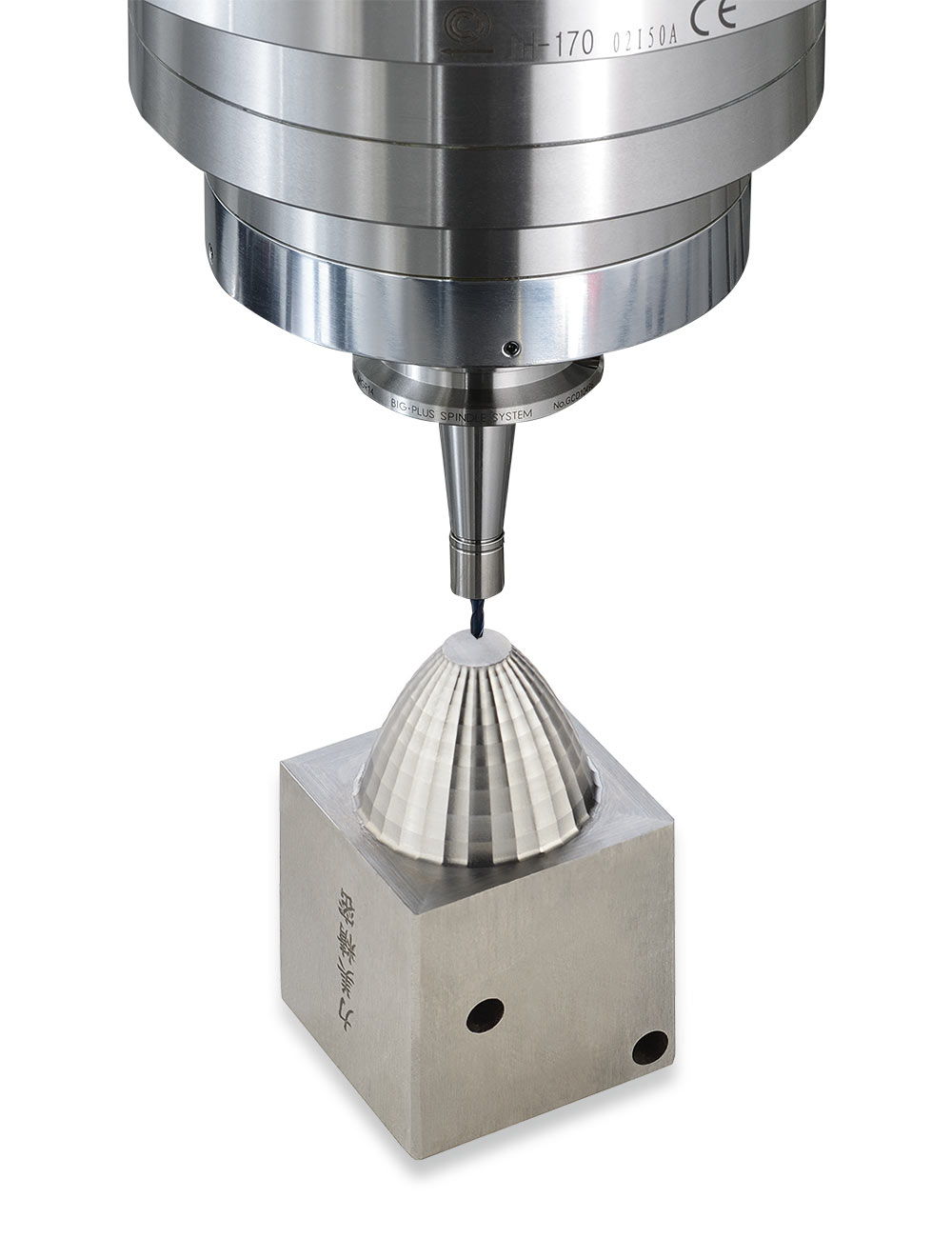

BUILT-IN TYPE HIGH SPEED SPINDLE

Spindle characteristics

- Powerful spindle motor driven by servo system with close loop control can feed-back any cutting condition to spindle motor, achieving to low speed-high torque & high speed-few vibration.

- Offer Rigid Tapping Ability.

- Oil-air lubrication retains stability during High Speed and Prolong.

- Oil-air lubrication connects with control system closely, and supplies different lubrication depending on different speed.

- 30 mins after spindle stop running, oil-air lubrication and air protection will shut down, to Reduce Air Consumption, Prolong Filter Service Life, and avoid oil drop from spindle nose.

HIGH EFFICIENCY

HIGH PRECISION

CUSTOMIZED

HIGH PRODUCTION

Featuring outstanding rigidity, humanized operation modes and maximum stability, the machine can also help to increase operator's efficiency.