CNC Double Column High Speed Machining Center

HMC–600 / HMC–1100

Extreme Stability in High Speed Machining

All structural parts are manufactured from high quality cast iron with annealing treatment, featuring outstanding material stability, high rigidity as well as lifetime accuracy. |

No counter-balance weight on Z-axis to ensure the surface accuracy in curved surface cutting. |

Z-axis rises automatically in case of power failure to avoid damage to the machine and workpiece. |

The spindle is designed with floating tool release that prevents the spindle from damage during releasing tool. |

| Specifications |

X, Y, Z-axis travel: 600 x 600 x 350 mm |

Double column construction features maximum stability in machining. |

Linear ways on all 3 axes. |

Rapid traverse rates on X, Y, Z-axis: 30/30/25 m/min. |

30,000 rpm built-in type high speed spindle. |

X, Y, Z-axis travel: 1100 x 750 x 500 mm. |

Double column construction features maximum stability in machining. |

Linear ways on all 3 axes. |

Rapid traverse rates on x, y, z-axis: 30/30/25 m/min. |

20,000 rpm high speed spindle. |

|

||||

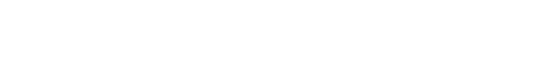

6 Blocks on Z-axis

|

|

|

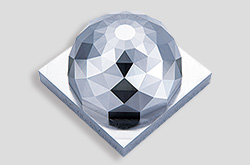

Extra Wide Base for Solid Support

|