Technical Information

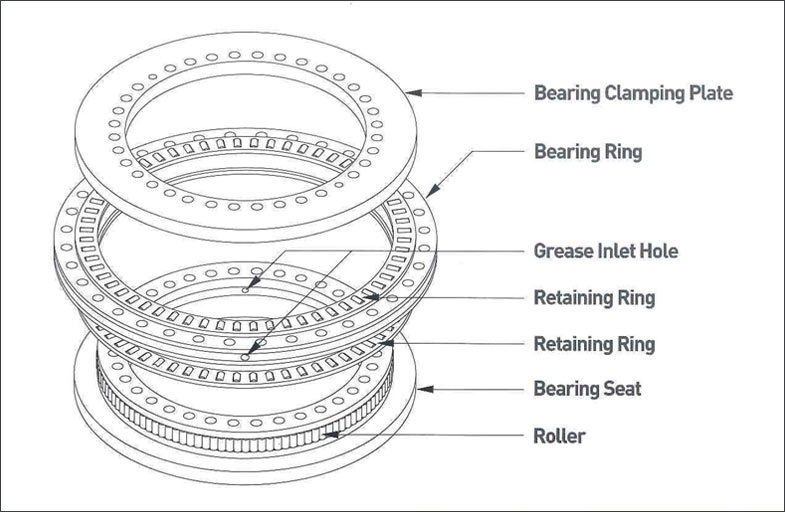

Structure of Rotary Table Bearing

Causes For Bearing Temperature Growth:

- Use of improper grease.

- Overload on rotary table bearing

- Incorrect bearing assembly

- Fill too much grease

- Exceed rated speed of rotary table bearing

- Rotary table bearing is damaged

Bearing Life

In general, the so called bearing life means load and running speed only without cosideation of other afected fctors. the bearin life calculated by the bearing life formula is only a theoretically estimated life, which is also called as "rated life".

There are many factors that may affect the bearing life, such as : load, running speed, Iubrication oil, temperature growth, noise, use environment and installation method, etc. Some unexpected factors may also affect the bearing life, such as : collision and pollution, etc. As such, bearing life is only a reference value and difficult to accurately estimate.

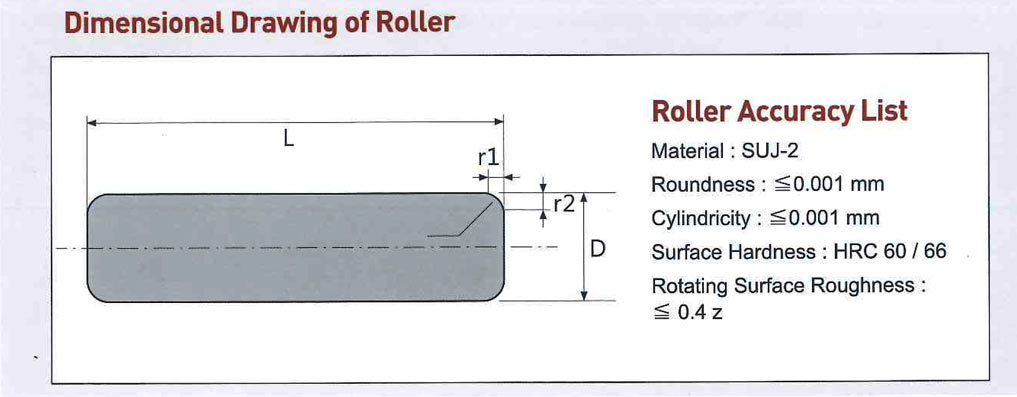

Importance Of Lubrication

The rotary table bearing is generally applied for running under a heavy load condition. If the operator ignore lubrication, it may cause heat due to excessive friction or even damage to the bearing. With an aim to ensure smooth running, low thermal growth, low wear for the bearing and extend its service life, the operator must periodically fill the lubrication grease.

Use only the well-known brand of grease. Do not use the lubrication grease from an unknown origin. If you have any question regarding the correct selection of lubrication grease, consult your local oil supplier or our company.

Filling Lubrication Grease

Although the lubrication grease may effectively reduce friction between bearing and parts, it is an important issue for using the correct lubrication grease. Note that using poor quality grease may cause a damage to the bearing. In addition, filling too much amount of grease may cause an additional drag force. Therefore, be sure to observe the following lubrication instruction for filling proper amount of grease at a proper time.

Feng Ying rotary table bearing provides grease inlet holes on the internal and external rings. Use a grease gun for shooting grease through the grease inlet holes. When shooting grease, it is suggested to slightly turn the external ring of the bearing for smooth oil filling and ensure uniformity of lubrication.

Oil filling frequency is once about every 3 months to half a year.

Recommended Brand Of Lubrication Grease

| Grease Brand | Grade | Grease Filling Frequency |

| Japan TOMKER | R2 | 3 months to half year |

Angle Measurement Encoder (Optional Accessory)

The steel band type angle measurement encoder employs a sensing type scanning principle for measurement. When using such encoder, any error caused by the installation of rotary table bearing, rotary table offset and bearing runout can be eliminated. This enables the rotary table rotation to achieve a higher positioning accuracy. The encoder features IP67 protection grade, therefore it can be mounted to near a bearing or contaminated position. The encoder provides various sizes to select.

Notice For Installing Rotary Table Bearing

The internal ring and external ring of the rotary table bearing have been fixed by screw before shipment. When installing the rotary table bearing, be sure to install the entire unit of the rotary table bearing without dismantling. In addition, note that an incorrect installation of spacing piece of the bearing may seriously affect the entire mechanism running performance. Make sure do not dismantle the rotary table bearing.

- During delivery, the marking on the internal ring and external ring of the rotary table bearing may be slightly offset. In case such problem occurs, loosen the fix screw on the internal ring or the external ring, then use a plastic hammer for calibration. After that, you can install the rotary table bearing on the bearing seat.

- When installing or removing the rotary table bearing, do not exert a force on the lock screws.

- When installing a flange, pay attention to the size tolerance of the part so that the flange can press the internal ring and external ring from the side.

- Before installing the rotary table bearing, be sure to thoroughly clean the bearing seat and the related parts.

- When installing the rotary table bearing, do not heavily knock on it by using a steel hammer. Only a plastic hammer is allowed for slight knocking until the rotary table bearing completely contact the bearing seat surface.

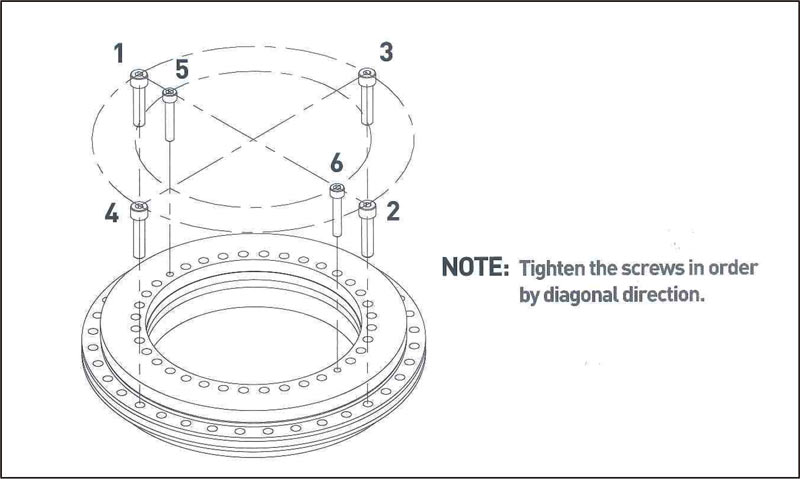

Screw Tichtening Instruction For Rotary Table Bearing

- In order to ensure the tightening force on each lock screw complies with the specified torque, it is necessary to use a torque wrench for tightening screws. Do not use a conventional wrench for tightening screws, as this will cause an inconsistent torque on each screw.

- The screw tightening force should not be too loose or too tight. Too loose tightening may cause the internal ring of the bearing to become loose. Too tight force may cause an excessive tensile force on the screw, leading to screw breakage or bearing deformation.

- SCREW TIGHTENING SEQUENCE: Tighten the screws in order by diagonal direction. Two times of tightening are suggested. For correct tightening torque, please refer to the " SCREW TIGHTENING TORQUE REFERENCE TABLE"