|

| SRU-2040 (Plunge Grinding) |

|

|

|

| A Combination of Technology and Precision |

| Advanced CNC Control |

The machine is equipped with the latest CNC control with teach-in programming and is easy to operate.

Machining programs are automatically generated through graphic dialog. This greatly saves on preparation time while increasing efficiency. |

|

|

|

| |

|

|

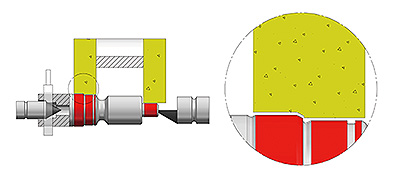

Grinding Wheel Spindle Supported by Hydro-static Bearing

The grinding wheel spindle is precision machined from Nickel Chromolybedenum alloy steel (SNCM-220). It is supported by hydro-static bearing, which greatly upgrades the spindle running stability while reducing temperature growth to a minimum.  |

|

|

| Plunge Grinding Grinding Examples |

|

|

| |

|

| |

| SPECIFICATIONS |

SRU-2040 |

Capacity

|

Distance between centers

|

420 mm

|

Swivel over table

|

200 mm

|

Max. load of centers

|

80 kg

|

| Max. external grinding diameter |

190 mm |

| Roundness |

0.8 μ |

| Machine Position Accuracy |

1 μ |

| Wheel head |

|

| Swivel angle |

±30° |

| Wheel O.D. x width x I.D. |

405 mm x MAX 70 mm x 127 mm |

| Wheel head travel |

180 mm |

| Max. travel |

180 mm |

| Min. setting unit |

0.001 mm |

| Rapid traverse rate |

6 m/min |

| Grinding feed rate |

0.01-6000 mm/min |

Table

|

Swivel angle

|

-3°∼+12° |

Max. travel

|

420 mm |

Rapid traverse rate

|

8 m/min |

Min. setting unit

|

0.001 mm |

| Grinding feed rate |

0.01-6000 mm/min+ |

Work spindle head

|

Spindle motor

|

SERVO MOTOR |

| Transmission type |

fixed / chuck |

Swivel angle

|

90°∼30° |

| Center taper |

MT4 |

Tailstock

|

Travel

|

20 mm |

| Center taper |

MT4 |

Motor

|

|

| Drive motor |

X-axis 1 kw |

| Z-axis 1.5 kw |

Wheel spindle

|

5HP |

Workload spindle

|

0.75 kw |

Hydraulic pump

|

2HP |

| Coolant pump |

1/4HP |

Machine dimensions

|

2730 x2500 x 1980 mm |

Net weight

|

3350 kg |

| Gross weight |

3600 kg |

|

| |

|

| |

| Standard Accessories |

Grinding Wheel and flange x 1 set

Diamond tool holde x 1 set

Tool box x 1 set

Carbide tipped work centers x 2 pcs

Coolant equipment x 1 set

Hydraulic pump with tank x 1 set

Work lamp x 1 set

|

|

| |

| Optional Accessories |

Internal grinding attachment (including 3-jaw chuck anode spindle)

Diamond tool holder for internal and external grinding wheel dressing (upward open type)

Diamond tool holder (tailstock mounted type)

Diamond tool holder for internal and external grinding wheel (sideward open type)

Angle trimming device

Radius trimming device

Cam locked driving dogs

Work steady rest

2-point steady rest

3-point steady rest

Adjustable 3-jaw scroll chuck

Adjustable 4-lock chuck

Magnetic coolant separator

Magnet filter with paper

Wheel balancing stand and arbor

Renishaw end face touch probe

O.D. measuring device- MARPOSS / TOKYO SEIMITSU |

|

| |

|