|

|

|

|

|

|

|

| SFB-B22 CNC BLOCK GRINDER |

| High Accuracy. High Efficiency. Multi-function |

|

The SFB-B22, a CNC block grinder developed by Sigma, is ideal for mass machining of small blocks. This machine integrates outstanding features such as multi-functionality, high efficiency, and lifetime accuracy. It is equipped with Mitsubishi / Siemens control systems for respectively controlling the wheel head feed and the table movement. Automatic loop grinding for ball grooves can be efficiently accomplished with only a single setup of workpiece. Multi-functions include: automatic wheel feed, coarse / fine / micrometric grinding, automatic step change for table, automatic workpiece speed change, pre-dressing to achieve wheel dressing, automatic compensation, automatic workpiece measurement (optional), and safety interlock of loop motions. Additionally, Sigma can provide users with expert CNC machining programs and wheel dressing programs for added convenience in machine operation. |

| |

|

|

| ¡@ |

Machine Structure & Features: |

|

The machine bed is manufactured from high quality cast iron (FC 300) with two times of manual aging treatment and natural aging treatment. In addition, the inside of the machine bed is constructed with uniform lattice shaped ribs for structural reinforcement and ensuring no structural deformation occurs. |

|

X-axis slideways are designed with high rigidity, high accuracy slideways that can retain long term accuracy, while ensuring travel accuracy, high rigidity, and working stability on X-axis. The wheel head feed is driven by servomotor in combination with ballscrew transmission, Feed accuracy is controlled by the built-in encoder. |

| |

|

|

|

|

|

|

| |

| SPECIFICATIONS |

|

SFB-B22 |

Capacity |

Max. width |

400 mm |

Max. length

|

800 mm |

Max. height

|

80 mm |

| Slideway type |

X-axis

|

Standard slideways (wear-resistant media) |

Y-axis

|

Roller type linear ways |

Z-axis |

Roller type linear ways |

Roller type linear ways

|

X-axis |

800 mm |

Y-axis

|

700 mm |

Z-axis

|

280 mm |

Transmission

|

X-axis |

Hyd. cylinder |

| Y-axis |

Screw |

| Z-axis |

Screw |

Table area

|

|

400 x 800 mm |

Feed rates

|

X |

20000 mm/min |

| Y(G0,G1) |

2000 mm/min |

| Z(G0,G1) |

3000 / 2000 mm/min |

Motor

|

Wheel spindle motor |

6.4 kw |

| X-axis |

Hyd. drive |

| Z-axis servomotor |

2.0 kw |

| Y-axis servomotor |

2.0 kw |

| Hyd. motor |

2.25 kw |

| Coolant pump motor |

1.5 kw |

Accuracy

|

Feed accuracy |

0.001 mm |

| Surface roughness |

|

| Parallelism |

0.002 mm |

| Net weight |

|

|

| Other |

Control system |

Mitsubishi / Siemens |

| Wheel motor |

Built-in type spindle |

| Wheel spindle taper |

Thread fastening M14 |

| Max. wheel size (Dep. On customer’s workp.) |

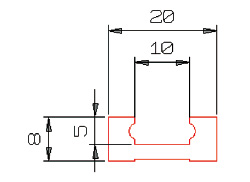

20 |

| Linear way |

PMI |

| Ballscrew |

PMI |

| Wheel dressing |

Profiled diamond grinding wheel |

| Enclosure |

Fully enclosed splash guard |

| Linear scales on Y,Z-axes |

Fagor |

|

| |

| Optional Accessories |

Machining Description |

Accessory

|

Quantity |

Brand |

Measuring device on machine

|

1 set |

Marposs or Toyko Seimitsu |

| Magentic filter |

1 set |

|

|

|

|

|

|

|

|

|

|

|