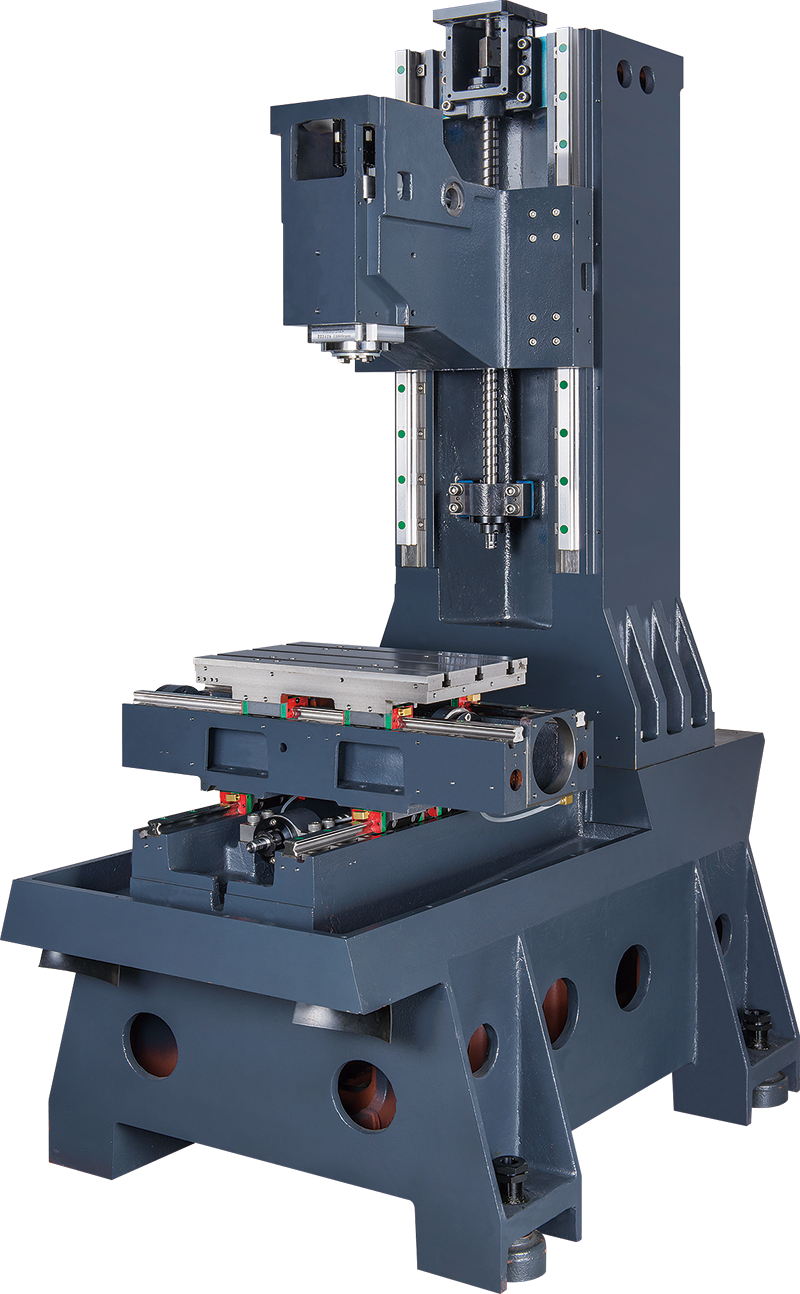

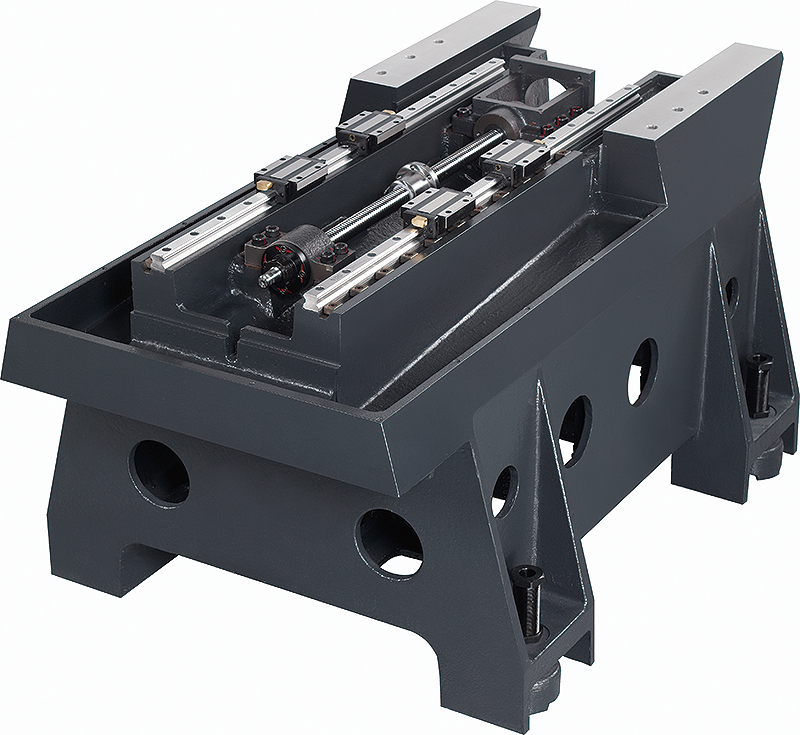

The base structure is reinforced by internal ribbing to achieve high rigidty and no deformation.

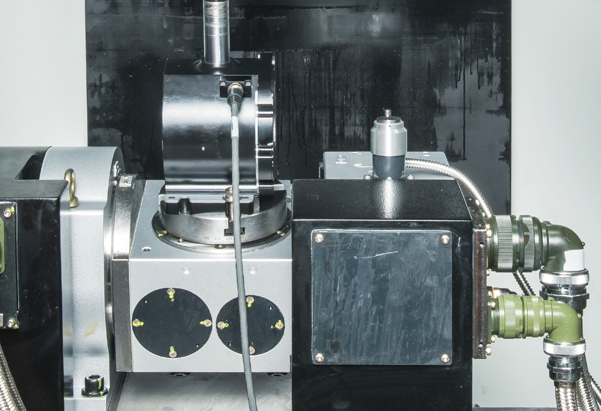

Front-mounted tool magazine.

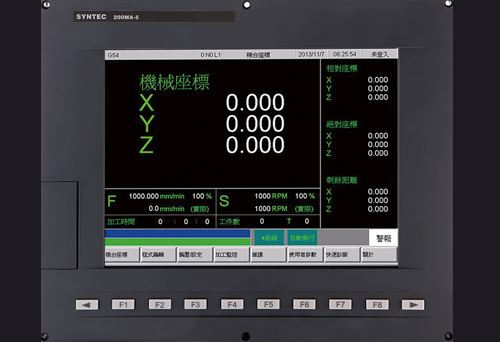

Xi Meng 5-axis vertical machining center is equipped with a SYNTEC 200 series controller, providing high-level machining functions, like 5 axes simultaneous control, tilted surface machining and tool edge point follow, etc. With the PC-base system, outstanding performance and easy intuitive operation, the machine provides optimum cost-to-performance ratio as you expect.

| MODEL | UNIT | VT-350-5X |

| SPINDLE | ||

| Spindle speed | rpm | 12000 |

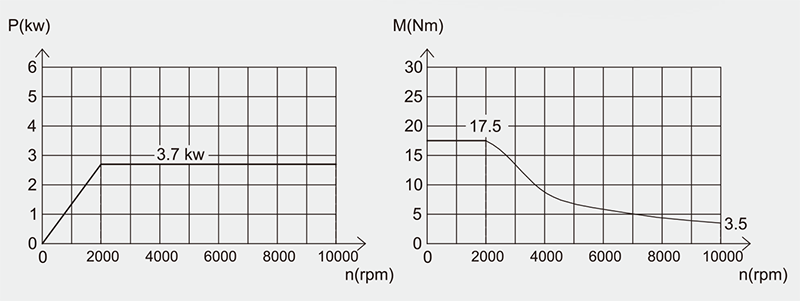

| Max. spindle power | kW | 3.7/5.5 |

| Spindle taper | BT30 | |

| TRAVERSE | ||

| X axis travel | mm | 350 |

| Y axis travel | mm | 270 |

| Z axis travel | mm | 300 |

| WORKING TABLE | ||

| Table diameter | mm | 400 x 250 |

| T-slot (WidexNo.xDist.) | mm | 12 x 3 x 80 |

| Max. table loading | kg | 200 |

| Spindle nose to working table surface | mm | 200~500 |

| Rotary table diameter / T-slot | mm | Ø125 / 12 H7 |

| Rotary table max. loading | kg | 0°-50 / 90°-35 |

| AXES | ||

| X / Y / Z axis ballscrew | mm | Ø25 x 16 x C3 |

| X / Y / Z axis servo motor | kW | 1.0 / 1.0 / 1.8 |

| X / Y / Z transmission system | Direct | |

| A/C AXES | ||

| A axis tilting degree | degree | 120° (+40°/-80°) |

| C axis rotation degree | degree | 360° |

| A/C axes rotation speed | rev/min. | 44.4 / 83.3 |

| A/C axes indexing accuracy | sec. | 50 / 40 |

| A/C axes repeatability accuracy | sec. | ±4 / ±2 |

| FEEDRATE | ||

| Rapid feedrate X / Y / Z | m/min. | 48 / 48 / 48 |

| Cutting feed rate | mm/min. | 1~10,000 |

| AUTOMATIC TOOL CHANGER | ||

| Tool number | tools | 16 |

| Max. tool weight | Kg/pc | 3 |

| Max. tool length | mm | 150 |

| Max. tool diameter | mm | Ø80 |

| SIZE | ||

| Air consumption | Kg/cm2 | 6-8 |

| Power rating | kVA | 15 |

| Lubrication pump | W | 100 |

| Coolant pump | HP | 1/4 |

| Machine weight | kg | 1600 |

| Machine dimension (L x W x H) | mm | 1690 x 1250 x 2150 |

• Due to continuous improvement and development, specifications are subject to change without prior notice.

• Auto lubrication system

• Coolant system

• Full enclosure

• Operation and programming manual

• Tool box

• Front-mounted 16-tool magazine

(BT-30)

• Heat exchanger

• Leveling bolts and pads

• Working light and 3 color alarm

indicator

• Rigid tapping

• FANUC Control

• MITSUBISHI Control

• Electronic touch probe (A.T.L.M)

• 24,000 RPM direct-drive spindle

• Automatic voltage regulator (A.V.R)

• Oil skimmer

• 4th axis rotary table

• Oil mist collector

• Chip conveyor

• Spindle cooler

Parts machining / Molds / Models / Automotive and motorcycle parts / 3C industries / Clocks and watches industry |

No.29, Ln. 1025, Fengzhou Rd., Shengang District, Taichung City 429, Taiwan.

TEL: 886-4-2563-0020, 886-4-2563-0120 FAX: 886-4-2563-0230

E-mail:cnc@yimeng.url.tw