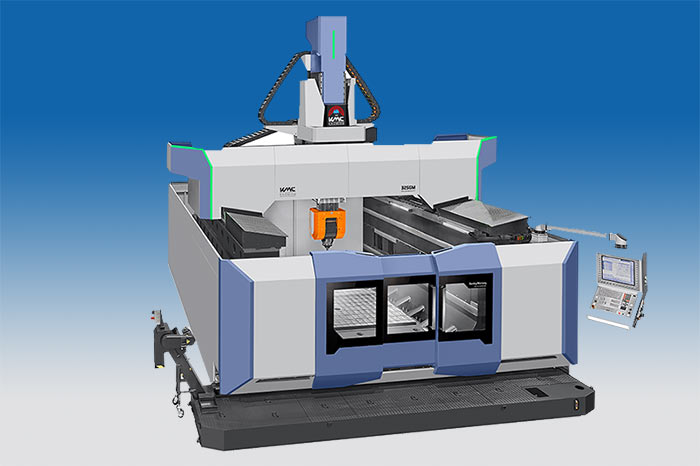

Revolutionizing Manufacturing: Introducing the KMC-325GM Intelligent Five-Axis Gantry Type Machining Center

In the ever-evolving landscape of manufacturing, precision and efficiency are paramount. With this in mind, we are thrilled to introduce the KMC-325GM Intelligent Five-Axis Gantry Type Machining Center, designed to meet and exceed the demands of the industry.

Major Korean shipbuilder Hanwha Ocean has swung to profit in 2023 amid a surge in sales. Consolidated net profit stood at 160 billion won ($119.8 million) last year, a sharp turnaround from a loss of 1.74 trillion won a year earlier, the company said recently in a regulatory filing. Sales jumped 52.4 percent on-year to 7.4 trillion won, but its operating balance remained in the red.

With a plethora of features, setting KMC-325GM apart from similar models on the market. At the core of its excellence lies a truly revolutionary one single-piece “BOX-IN-BOX” structure with the RAM placed inside of the saddle, and the saddle placed inside of the crossbeam. This rigid structure design not only minimizes the hanging problem but also maintains thermal symmetry during high-speed machining and ensures unparalleled stability, crucial for achieving the highest levels of precision in machining and an overall longer lifespan, benefitting both our customers.

Furthermore, our commitment to sustainable manufacturing is evident in the incorporation of energy-saving initiatives throughout the machine. Different from other thermal control modes, is limited valid the temperature within 25 degrees and 80% of the spindle speed. KMC unique coolant system controls the temperature from the original point rather than suppressing it after the thermal growth happens. Therefore, we not only apply a hollow ball screw, but a motor board with an oil circuit to isolate the temperature of the motor transfer the heat to the ball screw, bearing seat with an oil circuit to cut off the heat from the ball screw. This unique design is not only a KMC patent but a critical factor for us to win the “Taiwan Excellence Award in 2023”. Three axes cooling system not only enhances machine accuracy but also meticulously regulates machine temperature, guaranteeing optimal performance while minimizing environmental impact.

The superiority of the KMC-325GM extends beyond its innovative design. Equipped with a two axis swiveling head with a spindle speed of 15,000 rpm which can also be optioned to 30,000 rpm. Integrated table base with column design which made the columns easy to position. Of course without a leaking problem. Z axis is driven by two motors and two balls crews which increase 22% of the machining time without hysteresis. These ensure consistent quality and precision, crucial for aerospace manufacturing, automobile mold manufacturing, etc application.

In conclusion, the KMC-325GM Intelligent Five-Axis Gantry Type Machining Center represents a paradigm shift in manufacturing technology. With its innovative design, energy-saving initiatives, and unmatched performance qualities, it sets a new standard for precision, efficiency, and sustainability in the industry.

KAO MING is a leading innovator in manufacturing technology, dedicated to providing cutting-edge solutions for a wide range of industries. With a focus on innovation, quality, and sustainability, we continually strive to exceed the expectations of our customers and contribute positively to the world we live in.