Founded in 2003, INNOVATOR Machinery has pioneered veneer splicing technology to meet the growing demand for wood-textured products while minimizing the depletion of natural resources. In 2007, INNOVATOR Machinery took a significant step by acquiring technical cooperation rights, including the brand usage rights, with SAVI Industri A/S, a renowned Danish brand in the global veneer guillotine market. As a result, SAVI guillotines are now manufactured in Taiwan, maintaining European quality standards.

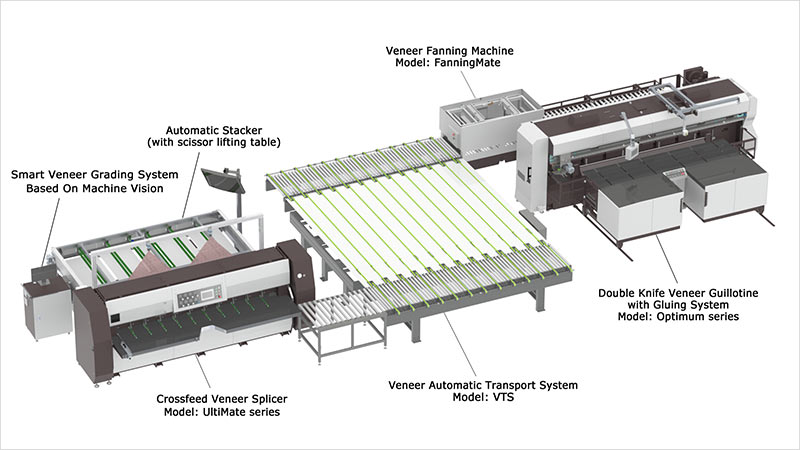

In 2015, INNOVATOR Machinery introduced the Smart Veneer Faces Production Line, specifically designed for automated production. This innovation not only reduces labor costs but also minimizes veneer face breakage caused by manual handling, while boosting production capacity. INNOVATOR became the first manufacturer of the Smart Veneer Faces Production Line in Asia, elevating its global ranking in veneer splicing technology to the top three.

In this rapidly evolving world, the constant driving force for INNOVATOR is continuous innovation and progress. The company is committed to developing an even wider range of advanced models to meet the diverse needs of its customers. Looking ahead, INNOVATOR's long-term goal is to become a leading global brand in the manufacture of veneer processing equipment.

The Smart Veneer Faces Production Line is meticulously designed to meet the automated production needs of our customers. It not only reduces labor costs but also minimizes the risk of veneer breakage caused by manual handling. This state-of-the-art production line streamlines operations that traditionally required eight to ten workers, now operating efficiently with just two to three employees. Equipped with a FIFO (First In, First Out) system, it optimizes waiting times for glued veneer strips, enhancing the splicing process and ensuring superior results.

Our Smart Veneer Grading System Based On Machine Vision integrates advanced computer vision technology with AI algorithms to achieve precise veneer grading. This system evaluates veneer quality, measures and records its dimensions, and collects detailed data on veneer bundles. With the help of an automated inspection system, this technology not only uncovers the true value of the veneer but also significantly reduces labor costs and production time.

Ultimately, this system guarantees that the true value of the final product is realized, delivering greater profitability and customer satisfaction.