24 August 2017

Plastic Industry Development Center

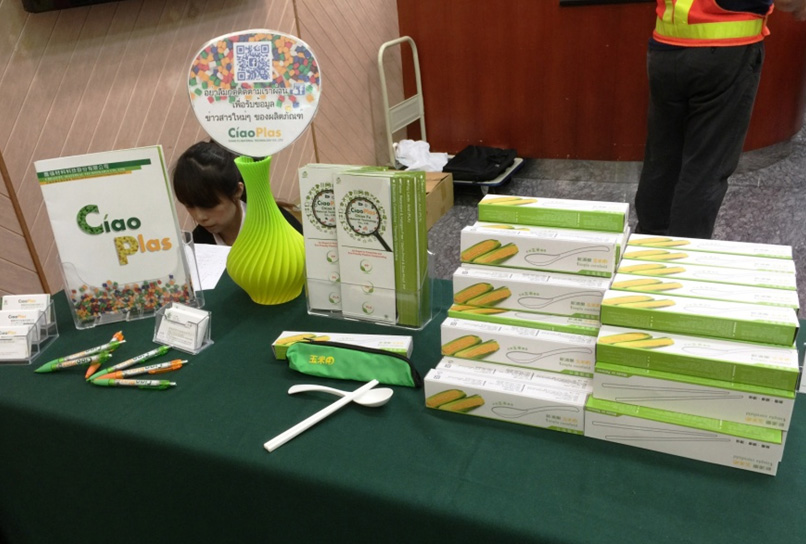

Chiao Fu Material

WWS editor/ Joy Wu

|

Today, Chiao Fu Material held a seminar on Applications for Biomass Materials and Composites in the Plastic Industry Development Center, attracting many customers and professionals in the industry. During this event, Chiao Fu Material not only shared its biodegradable, compostable plastic mulch film but also mentioned that its new functional plastic composite materials can be modified according to the needs of their customers.

Chiao Fu Material found that the demand for plastic mulch film has grown rapidly in recent years. In 2015, the market demand was worth USD 2.9 billion. By 2020, it is expected to reach USD 4.02 billion. To seize this business opportunity, Chiao Fu Material teamed up with the Council of Agriculture (COA), the Agricultural Technology Research Institute (ATRI), the Taiwan Agricultural Chemicals and Toxic Substances Research Institute (TACTRI), the National Chung-Shan Institute of Science and Technology (NCSIST), the Plastics Industry Development Center (PIDC) and Village Agricultural Production Cooperative in Miaoli County to improve plastic mulch film by adding plant fiber and heat-resistant bacteria. The organic matter generated during the process of natural decomposition of biodegradable plastic mulch film can turn into nutrients. Meanwhile, the bacteria added can serve as biopesticides to meet the goal of reducing pesticide usage. Experiments have shown that the biodegradable plastic mulch film can fully decompose in 1.5 to 2 months. In the future, Chiao Fu Material hopes to extend the time frame to 3 months. Although the biodegradable plastic mulch film bear a higher cost than that of the traditional PE mulch films, the farmers participating in the experiments all expressed their willingness to adopt biodegradable plastic mulch film. These farmers said that biodegradable plastic mulch film can not only can help save their time and labor but also erase the fear of contamination.

Chiao Fu Material adds different additives to raw plastic materials to produce new functional plastic composite materials that meet the demands from its customers. There are four types of functional plastic composite materials: conductive composites, thermal composites, halogen-free flame retardant composites and magnetic composites. The conductive composites solve the instable conductive/antistatic effects and the decarburization phenomenon while the thermal composites improve physical properties and whiteness. The halogen-free flame retardant composites resolve problems like product yellowing, small size, poor physical properties and poor temperature resistance. The magnetic composites containing metal components are modified to be rust-free and achieve good physical properties.