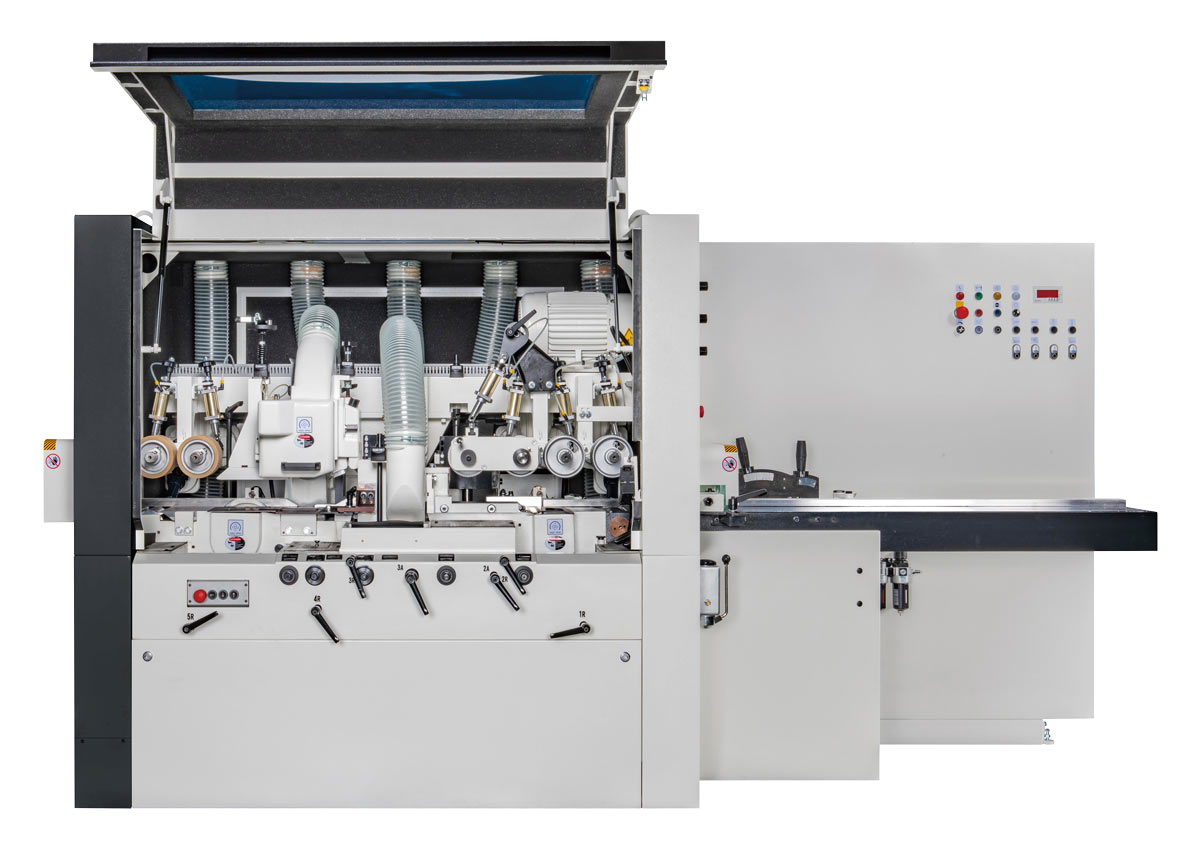

KENTWOOD M-100 Series

The KENTWOOD M-100 series represents the ideal first step into high-quality four-sided moulding, offering a blend of unique features, dependable quality, and affordability. The heavy-duty cast iron frame of this moulder machine guarantees precision and delivers superior finish quality, while its robust design and high-quality components of this woodworking moulder make it optimal for single and multi-shift use. The ergonomic design allows the operator to be more efficient, reducing cycle times and increasing production capabilities.

Performance Features

One-piece cast iron frame ensures maximum rigidity and vibration damping, while the standard sound enclosure enhances safety and reduces noise.

Faster feed speeds up to 24 meters per minute (80 fpm) for higher production efficiency.

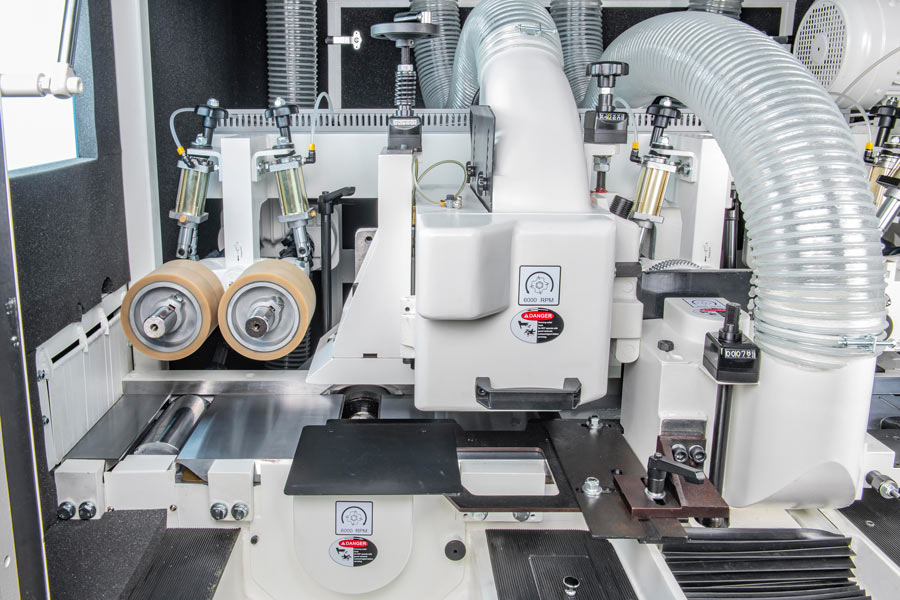

Adjustment of each spindle, except the last bottom spindle, can be easily performed using the front adjustment levers.

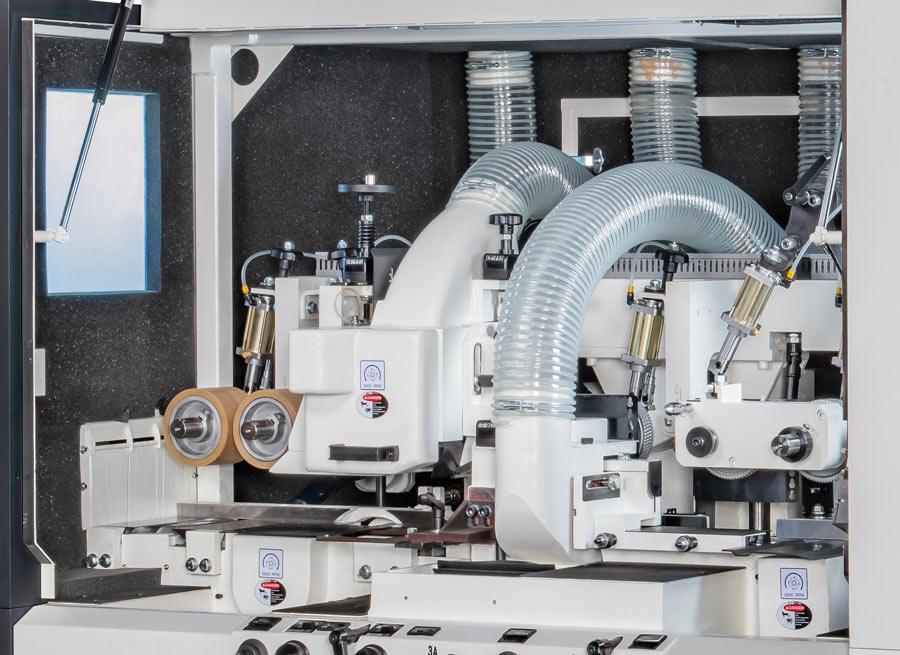

Spindles are powered by high performance Siemens IE3 motors with precion bearings, ensuring smooth, powerful, and reliable operation.

Spindle RPM up to 6000 for fine surface finishing.

Pneumatic top feed roll pressure provides consistent hold-down and accurate material guiding.

Table surfaces are hard-chrome plated for maximum wear resistance.

All manually adjusted points use permanent grease-lubricated bearings for maintenance-free operation.

M-100 Series

- Quality

- Affordability

- Feature-rich

- Small footprint